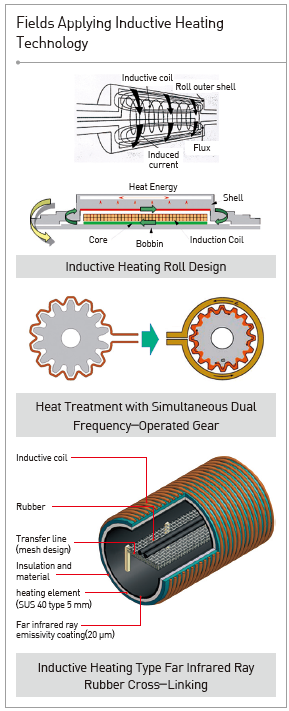

Induction heating refers to the process of coiling inductive coil around the object to heat and have the alternating current flow to create flux, and when eddy current created with the change in flux flows through the surface of the object, the material is heated by Joule heating created through the resistance. Electronic equivalent circuit is a transformer with short-circuit in secondary side. The conductive coil is primary side while the subject for heating is secondary side.

The use of such inductive heating technology is expanding in various areas such as electric smelting furnace, metal surface heat treatment, pipe electric welding, heating roll, and induction cooker.

Client / Market

- Can be applied in various industries–functional film, printing, packaging, laser printer, copy machine, metal melting, welding, surface heat treatment, shipbuilding, atomic power waste treatment, induction cooker, shoe leather, construction material, aircraft, medical devices, etc.

Necessity of this Technology

- Inductive heating roll inserts inductive coil inside the cylinder to have eddy current induced through a magnetic field that occurred through current flow heat the cylinder itself. Heat is generated directly from the surface of the roll and delivered to the film. Therefore, it has benefits of high thermal energy use efficiency, maximization of quality of film with consistent heat distribution on the roll surface, and simple and clean surroundings.

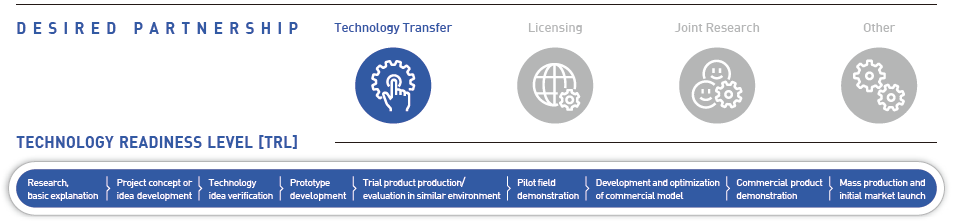

- When applying high frequency to the existing method of using inverter and matching circuit, only the upper part is heated, and when operated with low frequency, only the lower part is heated. The simultaneous dual frequency inductive heating technology that solves this problem allows for quick heating, prevention of through-hardening, and simplification of heat treatment process and contributes to improvement of productivity and precision of heat treatment.

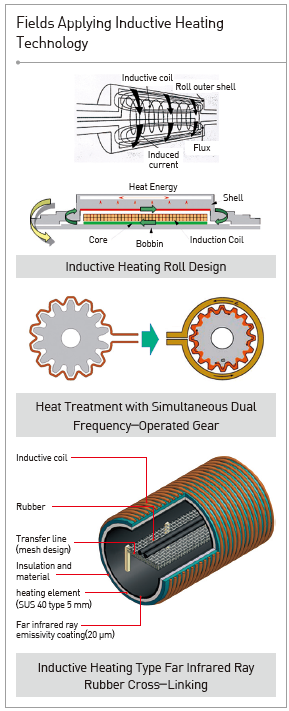

- Inductive heating type far infrared ray rubber cross linking facility uses the property of infrared ray where heat is penetrated quickly and deeply. The infrared radiation heater concentrates the radiation of the infrared ray in the cylindrical form, and the heating source of the heater uses the indirect induction heating technology to minimize the energy consumption.

- Until now, cross linking of rubber components used the hot-air method of applying heat from outside the rubber surface to conduct heat inside and shape the frame. However, with the infrared ray, the chemical changes in the rubber is minimal compared to the effect of the existing hot-air method.

Technical Differentiation

- With the contactless energy delivery property, the inductive coil does not have to be directly in contact with the object. Therefore, it enables effective and quick heating of various objects.

- No exhaust is generated as the process does not require oxygen for heating–heating done in clean environment.

- The entire or a part of object can be heated speedily as desired.

- With heat treatment of the surface or a specific area, it can be applied in various ways in the machinery and metal industry.

- Heating characteristic differs based on the material of the object, and the frequency and output can be adjusted to suit the material.

- Heating characteristic differs depending on the distance, and with the skin effect, heating can be done on the surface of the object, which enables surface treatment on a specific area.

- Recently, it began to be utilized for contactless energy delivery in the IT industry for delivery of electric power for magnetic levitation train, electric car charging, and mobile phone charging.

Excellence of Technology

- Inductive heating roll

- The surface temperature difference of the roll can be precisely controlled up to ±2 degree in the longitudinal direction that it can be used for superfine film heat treatment line such as functional film and FCCL line.

- Simultaneous dual frequency operating inductive heating technology

- The root and tip of the gear can be austenitized simultaneously (through-hardening prevention), only 1 cylindrical coil is used (existing method used inductive coil for each coil shape), the gear’s distortion or runout is minimized that post processing is unnecessary, and with instant heat treatment, energy is saved, and productivity is improved. Compared to existing carburizing heat treatment method, energy can be saved by 50%.

- Inductive heat type cylindrical far infrared cross-linking facility for extruded rubber

- Compared to existing hot-air drying facility, it saves energy over 30%, and compared to existing infrared ray facility using recently applied super steam’s drying characteristics, additional 10% of energy saving is expected.

- Since cross-linking device for extruded rubber is used broadly for rubber hose, cable, XL pipe, belt, and sealing band for car and more, commercialization of energy saving far infrared cross-linking device development is very likely as 50% of entire energy consumption at a plant is from hot-air dryer.

- As the result of measuring the tensile strength-the criteria for assessing the rubber quality, and 100% Modulus, the cross-linking quality of the rubber was found to be have improved by approximately 20%.

Current Intellectual Property Right Status

PATENT

- Inductive Heating Roll Design and Manufacturing Technology (KR0345157)

- Simultaneous Dual Frequency-operated Inductive Heating Technology Development (KR1136352)

- Far Infrared Ray/Super Steam Hybrid Heating Cross-linking Device for Extruded Rubber (KR1287572)

- Induced Heating Type Cylindrical Far Infrared Ray Cross-linking Device for Extruded Rubber (KR1096530)

KNOW-HOW

- Slit type core inductive heating roll technology

- Inductive heating roll design program

|