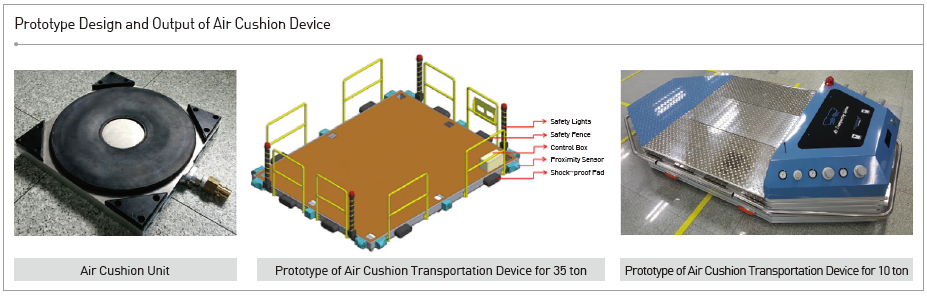

The air cushion device is also called air caster. It is a device that injects high pressure compressed air inside a flexible and durable diaphragm made of urethane and spouts high pressure compressed air on the bottom similar to the principle of air bearing to reduce friction with the floor and levitate a cargo (e.g. hovercraft, air hockey) for easy transportation of heavy weight object.

With barely any friction, a 500 kg cargo can be moved only with 5 kg of strength. It is 10 times more effective compared to existing wheel or caster method.

Client / Market

- Can be applied in almost all industrial fields for transporting heavy weight objects–shipbuilding industry, aircraft, machine tool, packaging, iron manufacture, mechanical machining, tire, national defense, marine plant, railroad car, construction machine, etc.

Necessity of this Technology

- Distribution welfare issue about active prevention of safety accident in labor-intensive workplace, reduction of damage from truck traffic accident, distribution security strengthening, expansion of distribution services in isolated areas, and improvement of quality of life for workers in the distribution industry has recently become an important issue that require political support.

- Improvements are needed to create human-centered, convenient work environment by improving situations at work that prioritize work and efficiency and considering the distribution laborers from the noise and safety aspects.

- Cranes are classified into fixed hoist and mobile, and regarding the work area, fixed hoist crane can only work within a specific distance while mobile crane can freely move. However, spacious safety distance needs to be secured for work.

- Forklifts are the best in terms of changeability for work and are widely used in general in the goods handling device market. The changeability is high for work area and work route, but there is a limit regarding the load weight and center of gravity that it is difficult to transport large objects. Also, depending on the center of gravity of the object, the carrying capacity of the forklift changes, which also limits transporting large objects.

- Air cushion device technology discharges high pressure compressed air from the bottom to reduce friction without a separate mechanism to lift a heavy cargo even over 30 tons. With a person simply pushing the carbo, it is likely to be applied for short distance cargo transportation or execution of work with high variability.

- This air cushion device technology surpasses the limitations regarding weight and volume experienced with forklifts that it can be specialized for variable, one-time transportation.

Technical Differentiation

- With barely any friction against the floor, a heavy weight object can be easily transported without damaging the floor or wall.

- The life of floor and wheel (when using together with this device) is extended as the heavy weight can be dispersed.

- It can be used in any direction, and it can spin 360 degrees on the spot, which allows for easy loading of a heavy weight object.

- With less vibration during transportation, it is favorable for transporting extremely sensitive heavy weight object such as aircraft components.

- It enables safe transportation inside a small place where high crane or forklift cannot enter or a space with height limit.

- Cost is low compared to existing crane and heavy equipment, and the volume is much smaller than the cargoes that working is easy.

- It can be used both indoor and outdoor.

Excellence of Technology

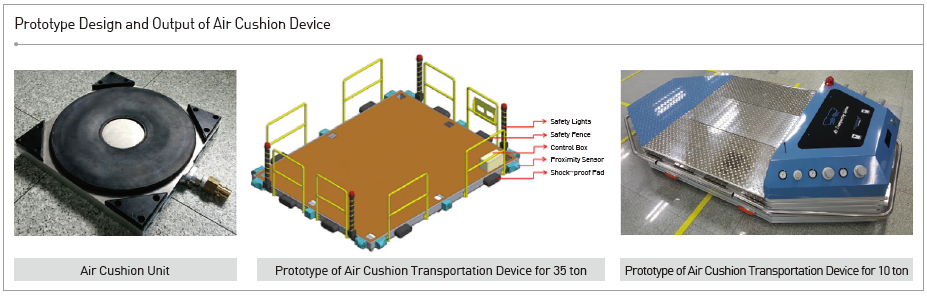

- Secured air cushion module design data through a CFD analysis

- The floatage test result using the air cushion module performance testing device was analyzed by collecting the applied load of the load cell L against the pressure applied to the air cushion as floatage data. As a result, it was measured that one air cushion can lift up to 6.2 ton, and when 6 cushions were used in parallel, approximately 36 tons could be transported. When lifting 6.2 ton, the air cushion could float the object 8 mm from the floor.

- By measuring the friction that occurs when transporting a 10-ton load using this air cushion device, the maximum static frictional force (Fs) was 146.8 kgf, and here, the coefficient of static friction (μs) was 0.0147. Considering that the coefficient of friction of the regular office flooring is 0.8, the rubber material of air cushion was only 1/63, and this confirms that the air film on the bottom of the air cushion is formed stably.

- Comparing the performance with a transportation device with wheels, the coefficient of friction for such device was approximately 0.1 that it was confirmed that the coefficient of friction for the air cushion is 1/8 times smaller. This means the air cushion has 8 times better transportation ability compared to a wheeled device.

- It was measured that the friction increased as the load (floatage) applied to the air cushion increased, and with 5 ton of load applied (when floatage is 5,000 kgf), the friction measured was 357 N. And the coefficient of friction here was 0.013. The friction coefficient tended to decrease as applied load increased.

Current Intellectual Property Right Status

PATENT

- Air Cushion Transportation Device (KR1777198)

- Air Cushion Transportation Device for Diaphragm Abrasion Prevention (KR1684390)

KNOW-HOW

- Technology for diaphragm material manufacturing and adhesion of shape from die

- Technology for design and analysis of optimal type of diaphragm based on capacity

|