High concentration/high purity ozone generation device technology that minimizes footprint and maximizes ozone yield characteristics through ultra-micro discharge gap for next generation semiconductor and OLED manufacturing process

Client / Market

- Semiconductor and FPD manufacturer/semiconductor/OLED/silicon solar cell cleaning field, Semiconductor ALD process, oxide film forming process, sensitive film removal process, water treatment field

Necessity of this Technology

- To apply for semiconductor process, a device is required to have high concentration of 12 wt% or higher, high-efficient ozone generating properties and low footprint for application in clean room. There is an urgent need for domestic development of ozone generator that meets these requirements.

- High concentration/purity ozone generator used for domestic semiconductor or OLED manufacturing depend entirely on import. Alternative domestic technology development is demanded.

- Domestic development of ozone generator mostly focuses on low-concentration ozone generating technology for food and beverage and environmental field such as water treatment.

Technical Differentiation

- Cleaning process of advanced electronic components like semiconductor and OLED is performed with a chemical solution-based, environmentally unfriendly, high cost process. As ozone water generation becomes easy with this high concentration ozone generating technology, the foundation for changing the cleaning process into an eco-friendly, low cost process has been established.

- The main idea of this technology is to design a high frequency/low voltage power supply device for designing discharge structure for increasing gas density inside the discharge area and high concentration ozone generation, which is done by forming an extremely fine discharge gap, to increase the conversion electric field strength for obtaining high concentration ozone by generating plasma with high efficiency.

- Minimize the size of discharge pipe for ozone generation and make a design that allows stacking and expansion according to the amount of ozone generation to fulfill minimization of the area occupied by the device inside the clean room, a main factor for semiconductor device development.

Excellence of Technology

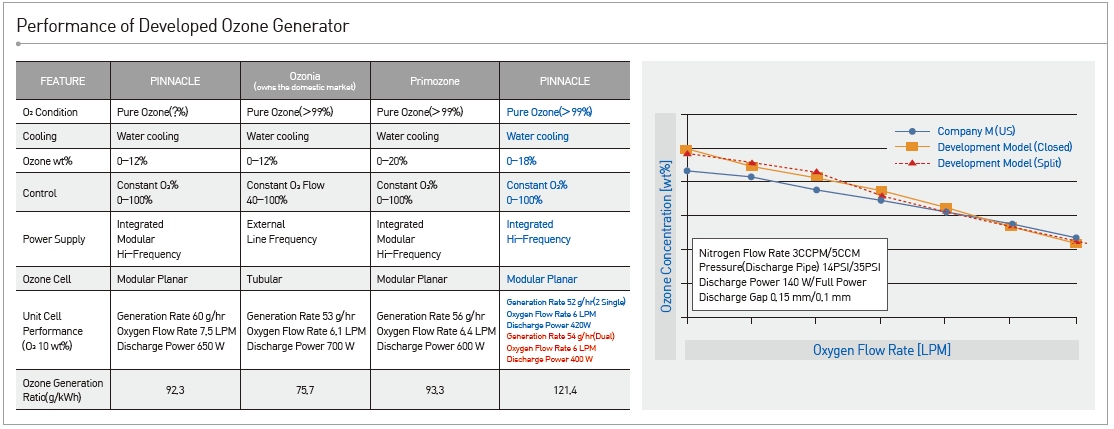

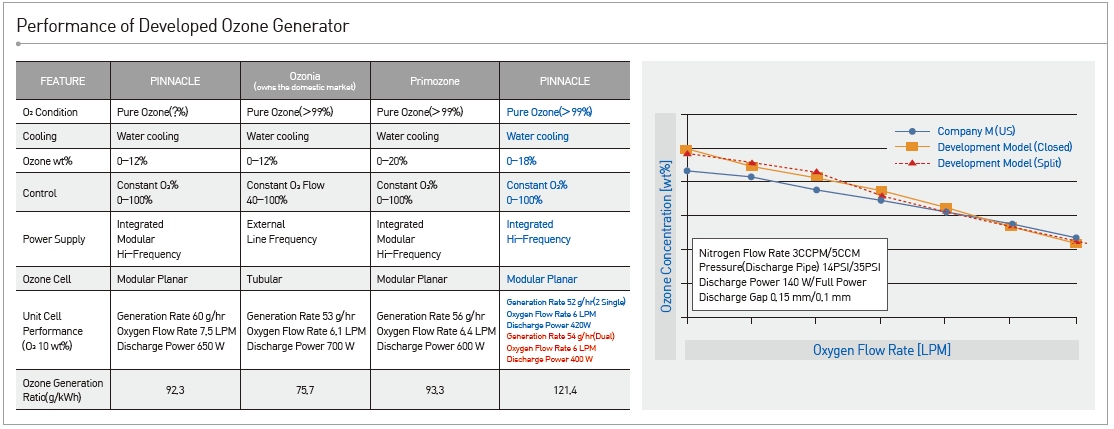

- The trial product test showed that the 14 wt% of high concentration ozone generation was obtained with the ultra-micro discharge gap formation and high-efficiency, high frequency power supply device.

- Under the same discharge area volume, approximately 1.5 times the ozone generating ratio was achieved-increased ozone generation amount and over 50% increase in generation ratio under the same discharge power.

Current Intellectual Property Right Status

PATENT

- Apparatus for Producing High Concentration and Purification Ozone Gas with Micro Discharge Gap (KR1109552)

- Apparatus for Generating High Density Ozone Gas Dissolved Water Using Electromagnetic Field (KR2014-0003109)

- Coincident Surface Discharge Type Apparatus for Generating Ozone Using Water-Electrode (KR1001858)

- Ozone Discharge Method of Using Coolant as Electrode and the Apparatus (KR515692)

KNOW-HOW

- High concentration ozone generator design and manufacturing technology

- High efficiency power supply device design and manufacturing technology

|