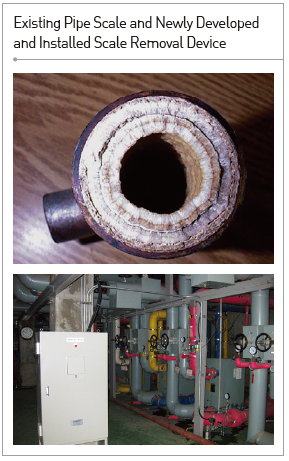

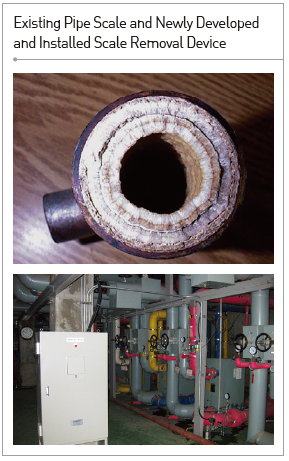

Scale removing and corrosion prevention device using Lorentz force through electromagnetic field from induction coil installed outside the pipe without using chemical substance

Client / Market

- General industrial facilities and all structures requiring fluid transmission for cooler, heat exchanger, boiler, and compressor

Necessity of this Technology

- Comparison of scale removal method

| Method |

Detail |

Drawback |

| Magnetic type |

Have fluid pass through the magnetic field to disturb molecular binding of Ca˖˖, Mg˖˖ ion and prevent solvent from adhering to the pipe wall |

Effect is insignificant unlike stated in the theory; issue of durability of magnet force |

| Electronic type |

Neutralize and eliminate the potential difference in water–metal surface to disperse ion on the heating surface |

Effectiveness in limited space |

| Supersonic type |

Continuously apply micro vibration to the water with ultrasonic waves from the ultrasonic oscillator for removal |

Can be used only within the limited range where ultrasonic wave can reach |

| Ion exchange resin method |

Remove scale by converting hard water into soft water |

Needed for corrosion prevention with Na˖ ion |

| Ion type |

Prevent oxygen in advance by adhering metal with higher oxidizing power than steel to control rusting and remove scale |

Effect differ depending on water potential level and pH, expensive cost Pipe cutting issue during installation |

| Catalyst type |

Change the magnetic properties of water to prevent rust and scale, Weaken coherence of rust and scale for removal |

|

| Inductive coil method |

Using Lorentz force in the magnetic field to accelerate CaCO³ union in the water to drain, and disassemble existing scale with CO² |

|

Technical Differentiation

- Smooth fluid flowing in the pipe such as coolant by removing scale at all times

- High-efficiency inductive coil type does not require replacement of existing pipe nor injection of chemicals.

- Energy saving effect from reduction in pipe loss in various systems including cooling system

- By having electricity flow through the coil installed outside the pipe, scale inside the pipe is removed with Lorentz force in the electromagnetic field.

- Red rust inside the pipe is changed into black rust (magnetite) to prevent corrosion.

- The effect is exercised up to 1 to 2 km downstream from the location where inductive coil is installed.

- The composition is simple consisting of inductive coil, power supply, and controller.

Excellence of Technology

- Development of scale remover to suit the domestic circumstances

- Can be applied for pipe for 1,000 W and with the diameter of 2,000 mm

- Change the square wave frequency sweep according to the test result (e.g. 100 Hz to few dozen kHz)

- Test on effectiveness on other matters other than scale removal (pipe rusting, bacterial infection) completed

- Possible to control the remover operation state according to the scale condition at the site

- Possible to monitor operation state by displaying related data while operating the scale remover

- Monitor the change in scale inside the pipe (relative changes) by installing a scale sensor

- Installation of current meter for easy check of operating point during installation and operation

- Control device displaying voltage, coil connection, operation signal, error and other alarm signals

- Possible to control the operating point by measuring the fluid running velocity when necessary

- Possible to control operating signal frequency and waveform for optimal scale removal

Current Intellectual Property Right Status

PATENT

- Scale Measurement Device for Pipe and Method (KR1379934)

- Electronic Pipe Scale Removal Device (KR1438765)

- Scale Measurement Device for Pipe and Method (KR2013 - 0124189)

KNOW-HOW

- System installation technology for simultaneous scale removal and corrosion prevention

- Technology for sweep frequency domain setting according to pipe and fluid type

- High-efficiency switching inverter driver design and manufacturing technology

|