Algorithm that analyzes the signal measured from main

components of the wind turbine to analyze/assess their health in

real-time and provides information required for operation and

maintenance(O&M).

It is based on the condition monitoring system (CMS) for real-time

diagnosis of the wind turbine system. While conventional CMSs

only detect existences of the fault, this technology provides the fault

diagnosis of main components and also predicts the remaining

useful life(RUL) of the components.

For the fault diagnosis and prediction of RUL in this technology,

big data processing and AI/machine learning techniques (neural

network, extended hidden Markov model) are applied to improve the

accuracy of fault diagnosis to 99%, and with the statistical inferences

including the Bayesian method and Monte Carlo simulation, the

error in estimated RUL was reduced to 10% or lower.

The fault diagnosis and RUL prediction for main components can be

effectively continued during the varying load due to the natural wind.

Client / Market

- Wind turbine, power plant, chemical plant, aircraft and railroad vehicle using power

train system

Necessity of this Technology

- To consider economic aspects, a large capacity wind power generation system is

built in a large complex and increase of the length of the blades for higher output

leads to increase in the load working on the tower and the blades itself, which

increases the risk of wind power generation system damage. Therefore, the

developments of diagnosis and maintenance technology to reduce breakdown time

and increase availability are critical to guarantee profitability of the plants.

- There is a need in offshore wind farm for technology development to monitor, diagnose

and predict the conditions of main components including blades, gearbox, and the

generator considering SCADA simultaneously in order to maximize availability.

- More than 40% of the faults in wind turbines installed in Europe in the past 20 years

were caused by faults of machines and components. But majority of wind turbines

installed in Korea are experiencing a serious difficulty with O&M due to contractrelated

or technical issues, and this is the results of inexperienced operation

techniques and insufficient condition monitoring technologies.

- Conventional CMS only detects whether the measured signal exceeds the normal

value or whether a fault has occurred. Therefore, prediction technology for faults is

necessary to enable active risk management of the target system.

Technical Differentiation

- Reliable condition monitoring and fault diagnosis through a distinctive 2-stage alarm system

- Existing industrial complexes have been operated for over 20 years and are in urgent need of safety management. Through

systemized risk management, an active risk management technology can be applied to allow highly efficient, low-cost

maintenance and life extension, which can be expanded to related fields.

- From the long-term aspect, diagnosis and condition-based maintenance (CBM) technology is needed to guarantee the system

soundness and reliability.

- Apply Algorithm and signal system that fulfills international standards (DNV·GL, IEC 61400-25)

Excellence of Technology

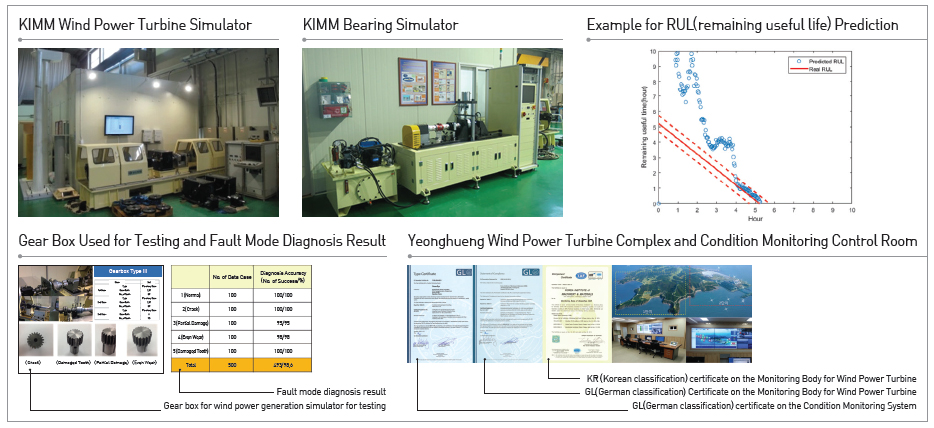

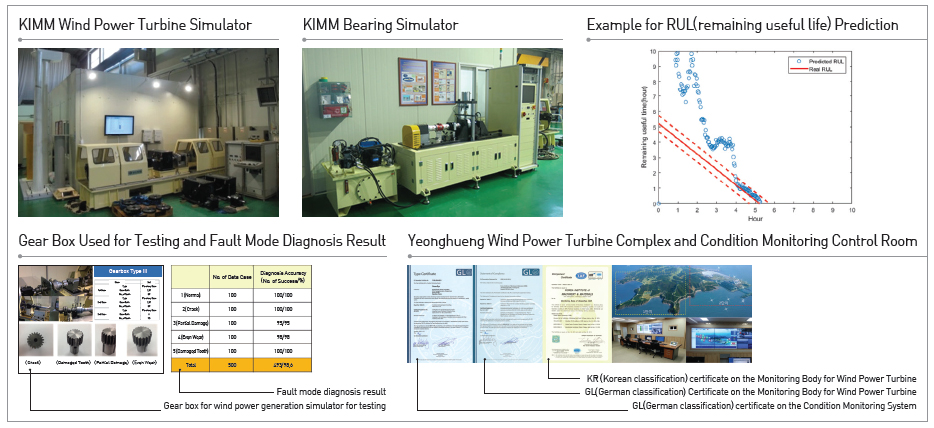

- Fault diagnosis and prognosis algorithms verified by using the wind power generation simulator

- Accuracy of fault diagnosis over 99%, RUL prediction error below 10%

- The fault diagnosis and RUL prediction for main components can be effectively continued during the varying load due to the wind

(characteristics of wind turbine operation), and the applicability and performance of this technology has been confirmed with the

data from an actual wind turbine.

- Acquirement of condition monitoring system (CMS) and monitoring body certifications from KR and GL.

- CMS installed and operated by 17 units in Complex 1 and 2 at Yeongheung wind power plant of Korea South-East Power Co., Ltd.

CURRENT INTELLECTUAL PROPERTY RIGHT STATUS

PATENT

- Condition Monitoring Apparatus and Condition Monitoring Method for Machinery System (KR1166871)

- Fault Diagnosis of Wind Turbine by Using Active Bin (KR1420846)

- Decimation Method for Measurement Data of Wind Turbine Condition Monitoring System Using Active Bins (KR1398072)

- A Method of Setting Alarm Levels for Condition Monitoring and Fault Diagnosis of Wind Turbine Generator (KR1599210)

- A System and Method for Monitoring Offshore Wind Turbine Structure (KR1740896)

|