Human-centric machine system safety technology for monitoring

surroundings of working machines such as excavator and collision

prevention

Client / Market

- Construction machinery (excavator, forklift, etc.) manufacturer, operator

- Construction/civil engineering business

- Local government for government-ordered construction

Necessity of this Technology

- An ultrasonic, image sensor cannot predict dynamic behaviors.

- Need to determine the safe time for braking considering dynamic properties of the

moving object.

- Active control of emergency stop required, more than a simple alarm

- Can reduce fatal accidents from construction site–high risk group within top 15% of

industrial accident

- Crucial core technology for the future considering the trend for machine safety

regulation and the speed of unmanned technology advancement

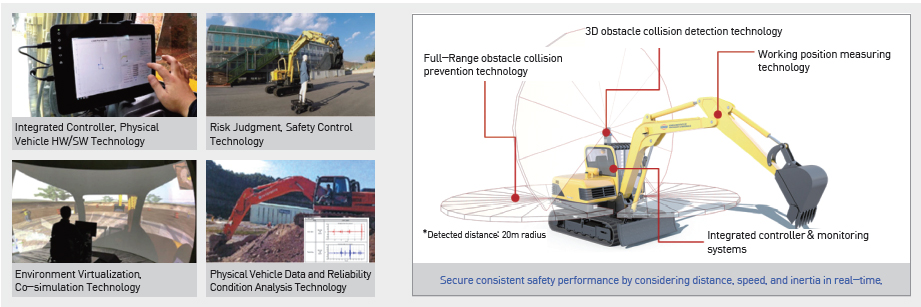

Technical Differentiation

- Developed a LiDAR-based technology with high resolution and precision with

existing image and ultrasonic sensor

- Developed a risk judgment algorithm enhanced from the simple distance-based to

consider time

- Secured consistent safe distance considering the inertia of excavator’s turning

movement

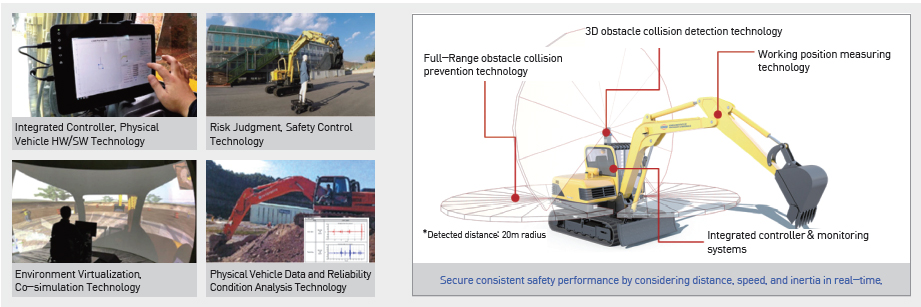

Excellence of Technology

- Full-Range (360 degree) obstacle monitoring technology

- Simultaneous recognition of multiple objects and algorithm computation within

100ms

- 3D obstacle collision monitoring technology

- Consistent safe distance (1 m±0.25 m) considering the inertia of excavator’s turning

movement

- Distance-based and time-based collision risk judgment algorithm technology

- Virtualization technology and reliability assessment technology

CURRENT INTELLECTUAL PROPERTY RIGHT STATUS

KNOW-HOW

- LiDAR data post processing (filtering, clustering, etc.) technology

- Object dynamic movement (speed) prediction technology

- Distance and time-based collision risk assessment

- Collision prevention safety control performance mounting/remodeling technology

for excavator, etc.

- LiDAR-based 3D environment recognition technology

|