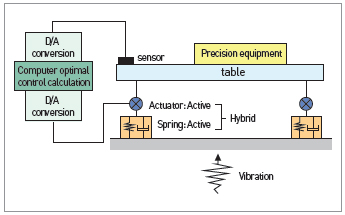

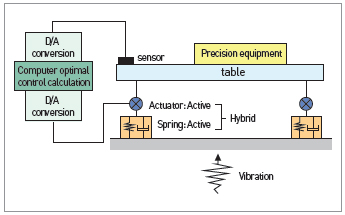

Technology to design and fabricate a novel mount system by

integrating a controllable actuator to enhance the performance of

the mount installed under an apparatus for vibration reduction

Client / Market

- Vibration proof mount manufacturer, manufacturer of device requiring low noise

and low vibration, defense industry, precision machinery industry, aerospace

industry, etc.

Necessity of this Technology

- Passive mount that is currently in use has satisfactory vibration reducing

performance, but a special industries demand development of a new mount with

vibration reduction performance improved by 10 dB or higher.

- A newly developed technology needs to reflect dynamic properties of active

elements that could improve the vibration reduction capability by 10 dB or higher

compared to existing mount while combining with passive elements.

- To develop a new mount demanded by the market, a technology to integrate existing

passive mount with an actuator that allows various controls is needed. However, the

passive mount and the actuator have their own dynamic properties that the design

and fabrication technology to be developed needs to accurately grasp them and

create a mount that could realize the characteristics the market demands.

Technical Differentiation

- A low-noise, low-vibration high-value added apparatus can be developed, and a

product for the defense market that demands special functions can also be developed.

- A new product that can fulfill the vibration limit condition of micro/nano-devices can

be developed.

- This technology is appropriate for customized products rather than ready-made

products, and added-value can be increased with it.

- Equipped with technology to develop optimized products that could fulfill various

requirements.

- Compared to competing technologies, it is considered superior in terms of cost.

Excellence of Technology

- A mount installed under an equipment supports the dead load of the equipment and

protects the equipment from external vibration to support the equipment to perform

its original function.

- Along with advancement of industries, development of a mount with better vibration

proof or shock resistant performance is required, and there is an increasing demand

for a hybrid mount that combines the passive mount and the active actuator.

- A hybrid mount that combines the passive air spring with a piezoelectric actuator,

an electromagnetic actuator or a pneumatic control actuator has been attempted.

- In the automobile industry, a hybrid mount that combines a passive rubber mount

with an electromagnetic actuator or MR/ER-compatible fluidic actuator is being

developed.

- For the field to be applied, different types of hybrid mount need to be developed,

and a hybrid mount development technology that considers the characteristics of a

passive mount and an active actuator from the design stage is demanded.

CURRENT INTELLECTUAL PROPERTY RIGHT STATUS

PATENT

- Vibration Absorbing Device in Type of Active Control (KR1373843, FR12/59138, GB1217352.2,

US13/628211)

- Active Control Type Vibration Absorbing Device Having Structure of Magnetic Flux

Leakage Reduction (KR1378034)

- Inertia Type Hybrid Mount for Vibration and Shock Suppression (KR1103059)

- Hybrid Electromagnetic Actuator Against Microvibration (KR1084987)

- Vibration Damping Device and Mount System Having the Same (KR1263259)

|