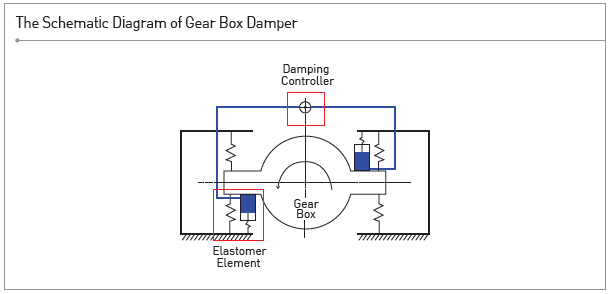

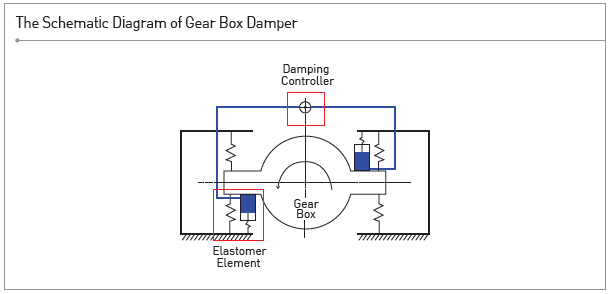

Semi-active damper that reduces the vibration from drive train by

controlling the vertical shock of the wind turbine gearbox using a

hydraulic chamber and damping controller

Client / Market

- Wind turbine manufacturer

Necessity of this Technology

- Existing technology uses a hydraulic cylinder for effective control of vertical

movement of the wind turbine gearbox at a specific excitation frequency and cannot

effectively respond to another excitation frequency when it suddenly enters.

Technical Differentiation

- Since the variable damping coefficient can be adjusted even if the excitation

frequency flowing from outside is changed, the variable damping coefficient that

minimizes the vertical displacement due to the disturbance of the hydraulic cylinder

is detected and the vibration is controlled.

- It is a semi-active damper that automatically controls the change of flow rate due to

hydraulic disturbance in passive damper using a commonly used hydraulic cylinder.

Excellence of Technology

- As shown in the figure blow, the elastomer consists of hydraulic chamber and a spring.

- There is one elastomer each below the left gear box arm and above the right gear

box arm, and the two are connected through a hydraulic line with the damping

controller in the middle of the hydraulic line.

- Rotational torque occurs in the gear box from the blade rotation of the wind turbine,

and the force from the rotational torque tries to change the volume of the hydraulic

chambers on both sides by the same amount, but the hydraulic chambers are

connected through the hydraulic line, therefore, the balance of the force is maintained

to suppress the rotary movement of the gear box and only allow vertical movement.

- As the gear box moves upward, the volume of the hydraulic chamber above the

right arm decreases, and the volume of the hydraulic chamber below the left arm

increases.

- Here, the oil moves through the hydraulic line, and damping force occurs from the

movement of the liquid.

- On the contrary, when the gear box moves downwards, the same damping force is

generated.

- Therefore, the damping force generated from the oil flow reduces the vertical

vibration of the gear box.

- Also, with the damping controller in the middle of the hydraulic line, the oil flow is

controlled to adjust the size of damping force, and the gear box vibration can be

reduced effectively.

- The senior researcher has 30 years of research experience in vibration analysis and

control for highspeed rotary machine and reciprocating machine system.

CURRENT INTELLECTUAL PROPERTY RIGHT STATUS

PATENT

- Apparatus for Dissipating Vibration Energy (KR1437362)

- Damper and Generator Damper (KR1437363)

- Torsional Vibration Damper (KR1073864)

|