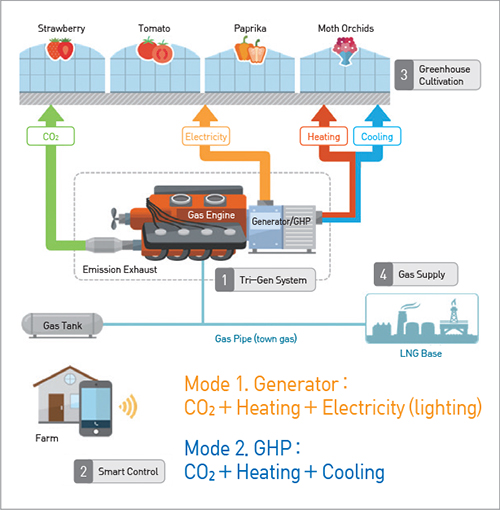

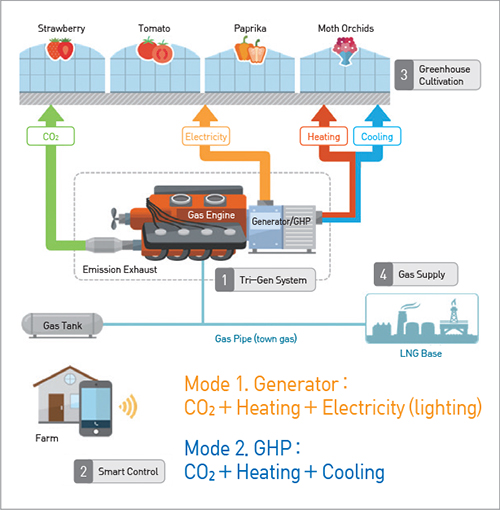

Tri-generation (Tri-Gen) system technology to produce and supply heat/CO²/electricity to horticultural greenhouse using gas fuels

Integrated smart energy control technology for growing flowers and vegetables using Tri-Gen system

Client / Market

- Gas engine heat pump (domestic market), gas engine generator (export market)

Necessity of this Technology

- Tax-free Diesel oil was mostly used for greenhouse heating, but with the abolishment of tax-free benefit for oil used for heating, the electric heating has been growing, which leads to national energy loss.

- Horticultural (greenhouse) area per person in Korea is No.1 in the world. Thus, the development of a new technology is expected to have a great ripple effect.

- Gas fuel price is expected to be stabilized in mid to long-term. Energy independence of future farms can be anticipated by decreasing electricity use and reducing CO2 emission,

Technical Differentiation

- Heating cost can be reduced by replacing oil fuel with gas fuel.

- CO2 enrichment cost can be reduced by replacing the use of liquefied carbon dioxide.

- Crop production can be expanded by controlling temperature and humidity through additional cooling and dehumidification

Excellence of Technology

- Tri-Gen (gas engine heat pump (GHP), gas engine generator)

- Energy consumption is reduced through integrated management of greenhouse energy using a GHP. With the all-in-one system of GHP, investment cost can be saved by avoiding unnecessary installation.

- GHP has 30% higher heating efficiency than a boiler (over 1.5 COP). Temperature and humidity can be controlled by providing cooling during summer in order to extend crop production; all day cooling for flowers and night-only cooling for vegetables. And photosynthesis is improved by supplying CO2 in the exhaust gas. All these contribute to increasing farmer’s income by significantly improving crop productivity.

- Gas engine generator is not appropriate for domestic greenhouses, where electricity for agricultural purpose is cheap in Korea. However, it can be suitable for Central Asia and Middle East regions that are rich in resource with limited electricity infrastructure.

- Gas engine for horticultural energy source

- An original gas engine with reduced emission was developed for carbon dioxide enrichment by supplying the exhaust gas from the engine.

- With CO/NOx < 25 ppm, the gas engine development goal was achieved. No damage has been reported after the long-term tests from 5 demonstration sites.

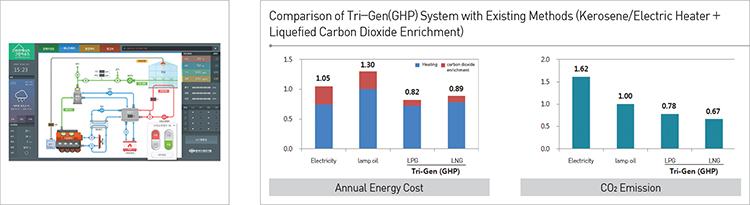

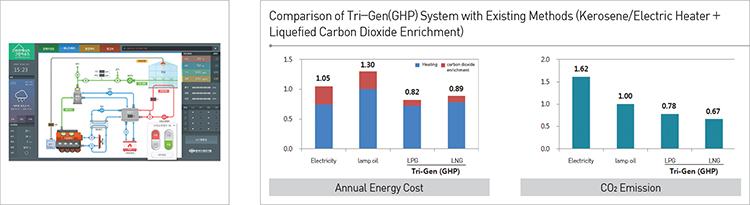

- Comparison with existing method

- Annual energy cost (heating cost + carbon dioxide enrichment cost) Possible to reduce by 30 to 40% (compared to kerosene heater)

- Possible to reduce CO2 emission by 50 to 60% (compared to electric heater)

- Expected farmers’ income (1 ha paprika greenhouse) 50 to 70 million won (payback period of 2 to 3 years)

- Support measures such as installation aid, gas price benefit (tax free), CO2 emission reduction certification

- Tri-Gen smart energy control system (remote/automatic control)

- Measurement: Temperature/humidity/CO2 concentration in the greenhouse, outdoor weather station (light intensity /wind speed), engine emission concentration

- Control: Heating and cooling/carbon dioxide enrichment/lighting/various thermo-fluidic devices

Current Intellectual Property Right Status

PATENT

- Independent Energy Supply Module for Horticultural Greenhouse Utilizing Trigeneration Technology (KR1784878)

- Tri-gen System for Horticulture Utilizing Carbon Monoxide Sensor (KR1784896)

- Tri-gen System for Horticulture Utilizing Ultra Low Emission Gas Engine Skill with Low Pressure Fuel Condition (KR1769438)

- Tri-generation System Using Engine to Selectively Use Liquefied Petroleum Gas or Natural Gas, and Control Method Thereof (KR1712904)

- Tri-generation System Using High Lean Burn Operation and Control Method Thereof (KR1569677)

KNOW-HOW

- Integrated control technology of greenhouse environment, energy using Tri-Gen

- Greenhouse vegetable/flower growing technology using Tri-Gen

|