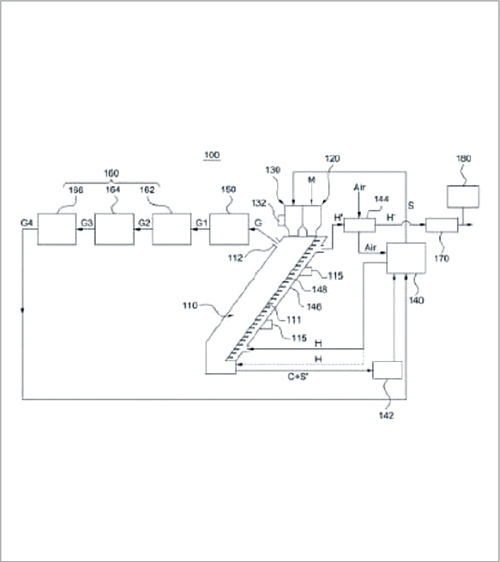

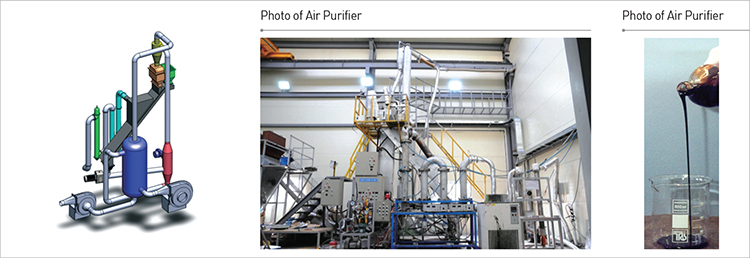

Bio-crude oil production apparatus, system, and method for efficient bio-crude oil production from biomass using fast pyrolysis method

Client / Market

- Bioenergy-related company

Necessity of this Technology

- Bubbling-fluidized-bed system for bio-crude oil production requires a large amount of fluidized gas for sand fluidization, so it needs large size of reactor and pipe with expensive installation cost. Moreover, a lot of undesirable charcoal remains in bio-crude oil because the pyrolysis vapor flows out with bio-char prior to the separation process.

Technical Differentiation

- Fast pyrolysis of biomass using this technology does not require the fluidized gas supply, so the facility size is reduced and the installation cost becomes cheaper.

- Fast pyrolysis of biomass using this technology can control heat and mass transfer optimally to maximize the bio-crude oil yield and to produce high quality bio-crude oil with less charcoal.

- Bio-crude oil can be combined to bio-refinery industry, and enable the active coping with certified CO2 emission reduction due to its carbon neutrality.

- This bio-crude oil production system has a simpler structure compared to existing bubbling fluidized bed, circulating fluidized bed reactors, therefore its size and construction cost can be reduced to 2/3 level.

- Pyrolysis-vapor and bio-charcoal are separated during the bio-crude oil production process, and this allows the production of bio-crude oil with high quality.

- It does not use carrier gas which affects the reactor operation condition, which enables an easy plant operation.

Excellence of Technology

- Over 10 papers on this technology were published in international journals, and related patents were registered in 7 countries.

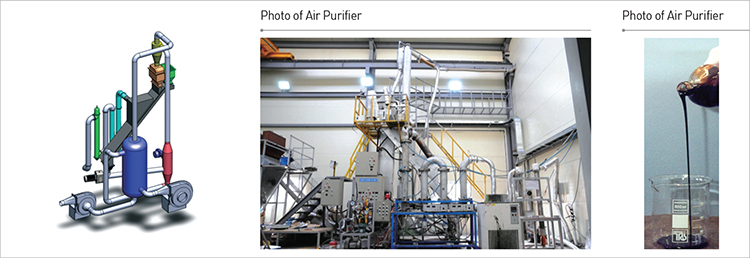

- Several delegations from Philippines, Cambodia, Rwanda, and Ghana have visited this plant, and they showed high interests in the utilization of this technology in their countries.

- Performance test in pilot plant of 20 kg/hr showed the bio-crude oil yield of 65% that is comparable to advanced countries. Semi-commercial scale plant of 200 kg/ hr, largest in Korea, is under construction.

- Patents for bio-crude oil manufacturing apparatus, bio-crude oil manufacturing system and method were registered in Korea and abroad (USA, Canada, China, Japan, Germany, Finland, Sweden).

Current Intellectual Property Right Status

PATENT

- Device for Manufacturing Bio-oil, System for manufacturing Bio-oil and Method for Manufacturing Bio-oil Using the Same (KR0946714, US9005313, CA2762961, JP5633828, CN102449117, EP10780769.5)

- Fast Pyrolysis Reactor and Biocrude-oil Manufacturing System Using the Same (KR1068748)

- Apparatus for Manufacturing Bio-oil Using Fast Pyrolysis of Fluidized Bed (KR1285879)

- Apparatus for Collecting Bio-Steam and Apparatus for Manufacturing Bio-oil Having the Same (KR2012-0113240)

- Condensing Device (KR1175094)

- Biocrude-oil Manufacturing System with Improved Fluidization and Heat Exchange (KR2014-0026713)

- Biocrude-oil Manufacturing System with Multi-stage Condensation (KR20140026716)

|