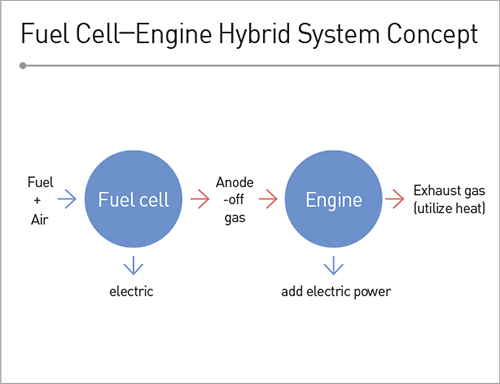

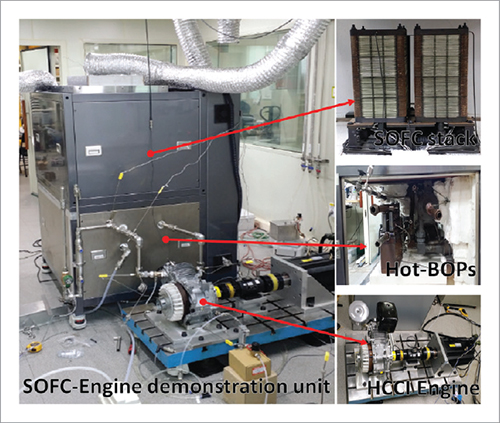

Developing high-efficiency distributed power generation technology by combining SOFC and HCCI type internal combustion engine

In the proposed fuel cell-engine hybrid concept, unreacted fuel released from the fuel electrode (anode off-gas) is burnt in the HCCI engine, generating additional power.

Client / Market

- Fuel cell system developer, energy suppliers for district, distributed power generation system developer/operator

- High-efficiency distributed power generation system (RPS market, Energy system for public buildings, Distributed power generation market)

- Expected supply expansion of distributed power generation system in future (for building/group energy, etc.)

- Power generation system for marine application (propulsion system and/or auxiliary power unit)-opening new application field using high-efficiency system for large ship (to cope with EEDI regulations)

Necessity of this Technology

- As fuel cell technology is approaching to commercialization, much attention has been giving to the technology of efficiency improvement

- To improve the system efficiency of fuel cell power generation system, there exist several important and effective approaches: (a) improving fuel cell stacks’ efficiency, (b) system optimization, (c) reducing BOP power consumption. Among the ways, (d) hybrid system is feasible option when considering the current technical limitations of fuel cell. Existing hybrid systems mostly considered the combination of fuel cell and gas turbine; however, for a distributed power generation in the range below several hundred kW, fuel cell-engine hybrid is more favorable, which integrates a fuel cell and an internal combustion engine (performance, durability, equipment cost, etc.).

- The proposed fuel cell-engine concept can be applied to the atmospheric pressure fuel cell; the anode off gas from the fuel cell can be effectively utilized by the internal combustion engine, generating additional power and contributing to efficiency improvement. Efficiency improvement results in a substantial decrease in equipment cost, fuel use and relevant cost, and CO2 emission. The fuel cell hybrid shows efficiency improvement of 5 to 7 percentage point; the LCOE can be reduced by 10% or more.

- The anode-off gas contains fuel substance under 15%; therefore, complete combustion cannot be easily achieved. By optimizing the design of the engine and control scheme of the engine, complete combustion has been achieved, showing very low unburned remaining fuel composition at the tail gas. In addition, the engine design, interface between the fuel cell and engine is of much importance for a stable operation; design and control know-how has been obtained.

Technical Differentiation

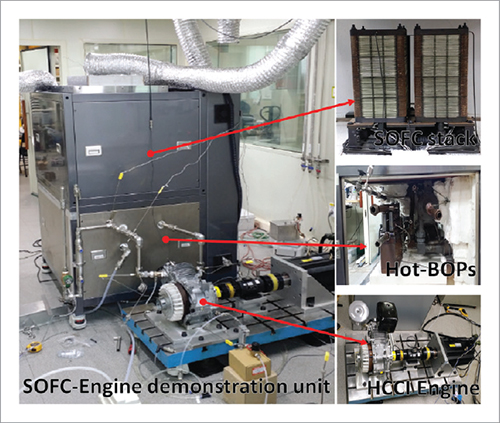

- The fuel cell-engine hybrid system is a promising technology that significantly improved the generating efficiency being compared to the existing fuel cell systems. The research team has successfully developed and operated the demonstration system for the first time in the world.

- Through demonstration system operation, it has been verified that the efficiency increases by 5.3 percentage point. (Efficiency improvement of 5% or higher in a small-scale system is a very challenging target and very promising result. Also, based on the test results, engineering technology for scaling-up to 100 kW-class system has been obtained.

- Korea’s best system technology has been secured in terms of capacity and efficiency. The technology will be further developed to be scaled-up large capacity system and to reach commercialization.

- Various know-hows and technologies are secured for development of a large capacity generation system.

Excellence of Technology

- Analysis/design technology for fuel cell-engine hybrid generation system, main component design technology, and system integration and operation control technology have been secured. World’s first operation for concept demonstration has been successfully conducted.

- Fuel cell-engine hybrid system is a novel concept and it is a very promising technology in all aspects: efficiency, economics, and operability. Application to various fields will be attempted, for example, building, industrial park, propulsion system for large ship, etc.

- (System integration and operation control technology) Newly developed hybrid system consists of various components like fuel cell, engine, and reformer. The system optimization and operation control technology has been secured. The system has been continuously and successfully operated during 200 hours without any serious problems.

- (SOFC stack scale-up technology) SOFC stack scale-up technology for 5 kW with efficiency over 50% has been secured.

- (HCCI engine combustion technology) Fuel cell anode-off gas ultra-lean combustion technology has been secured.

- Homogeneous charge compression ignition (HCCI) engine control technology has been secured. NOx emission is successfully controlled under 10 ppm.

- (Reformer and steam separation technology) Reformer heat transfer optimization technology and steam separation technology have been secured.

- (Modeling & Simulation) Modeling and simulation (M&S) technology that satisfies both accuracy and calculation speed has been secured

- Paper publication and academic conference presentations: 11 SCI(E) papers, 6 domestic papers in Korea, 20 international academic presentations, 62 domestic academic presentations

Current Intellectual Property Right Status

PATENT

- High Efficiency Fuel Cell Hybrid System (KR1440191, KR1358095, US13/469142)

- Method of Warming-up in Fuel Cell-Engine Hybrid System (KR1653372)

- Fuel Cell-Engine Hybrid Power Generation System for Distributed Power Generation Which Has a Cooling Device (KR1735647)

- Fuel Cell-Engine Hybrid Generation System (KR1690634, KR1690635, KR1690636, KR1690637, KR1690638)

KNOW-HOW

- Fuel cell power generation system analysis technology (process modeling, economic feasibility assessment, life cycle assessment)

- Fuel cell system simulation technology/Flow distribution technology for multiple fuel cell stack use

- Engine ultra-lean combustion technology for hybrid system application

- High temperature component design and hot box thermal design technology

- Fuel cell-engine hybrid system control technology

|