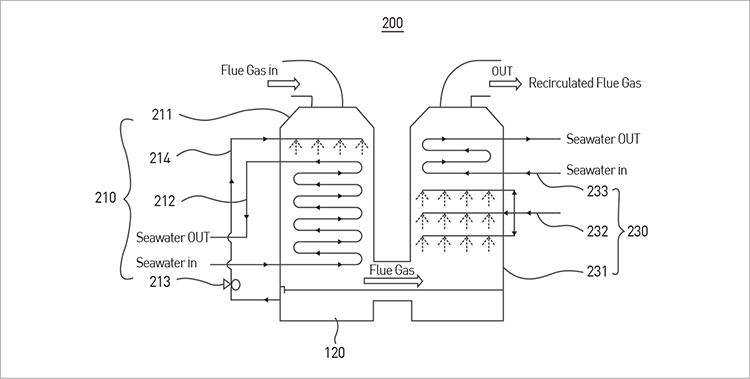

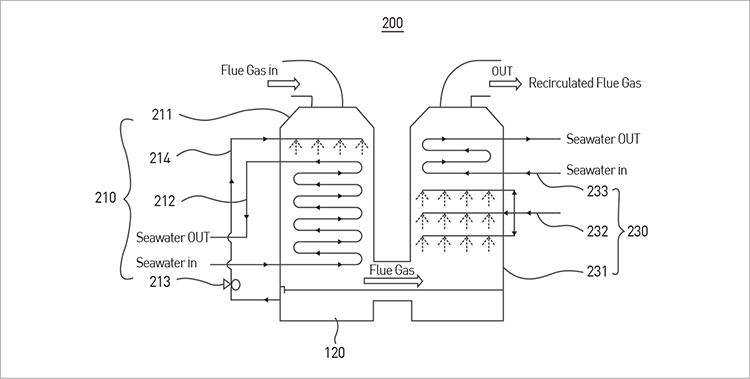

Technology to remove moisture and sulfur oxides in flue gas by cooling the flue gas to condense moisture and use the condensate water to remove sulfur oxides

Client / Market

- Thermoelectric power plant, electronic and chemical process facility

Necessity of this Technology

- By combining condensation and sulfur oxides removal as one process and using condensate water as process water, additional wastewater generation can be prevented.

- When using existing method to remove moisture and sulfur oxides, wide installation area and high installation cost are burdensome, and it generates a large amount of wastewater.

- To apply the CCS (CO2 capture & storage) technology for the thermoelectric power plant, the flue gas recirculation technique needs to be adopted, but in this process, the facility may be damaged due to concentration of water and sulfur oxides.

Technical Differentiation

- Compared to individual facility composition, the installation area and cost is reduced by 1/2 or more.

- It can be applied without greatly affecting the process of currently operating system or moving the facility.

- It is easy to handle the properties of various imported coals and changes in process.

- By using the seawater, water and energy consumption is reduced to 1/10 level.

- As condensate water is used to remove sulfur oxides, there is no additional wastewater generation, and wastewater treatment process is unnecessary.

Excellence of Technology

- The technology is applied to the pilot Oxy-PC thermoelectric power plant.

- Seawater is used to condense moisture in flue gas, the pH of the condensate water is controlled, and the condensate water is resprayed to the flue gas for enhanced condensation effect and quick removal of sulfur oxides.

- By using the seawater to condense moisture in flue gas, the moisture content is dropped from 25% to 4%. By using condensate water along with the seawater, the condensation effect is maximized.

- Based on the incoming concentration, the sulfur oxide concentration level of several hundred ppm is dropped to 10 ppm or below and discharged, and this prevents sulfur oxide concentration and facility corrosion damage from flue gas recirculation.

- It was applied to the 0.7 MW level pilot pure oxygen thermoelectric power plant system, and its function and efficiency were confirmed.

Current Intellectual Property Right Status

PATENT

- Fuel Gas Condenser for Sulfur Oxide Removing (KR1282918)

|