Heat exchanger (evaporator) design technology for low GWP

refrigerant, which is the alternative refrigerant of current HFC/

HCFC’s for global warming prevention

Client / Market

- HVAC&R component and system business

Necessity of this Technology

- Problem of Existing Technology

- As the time for the HCFC’s refrigerant use restriction arrives, HFO’s refrigerants are being developed to replace HCFC, and relevant researches on performance and cycle development of HFO’s refrigerant is required.

- Existing refrigerant are regulated for used from 2030.

- Necessity

- System performance estimation: Companies designing/manufacturing low GWP HVAC&R system require cycle design technology and performance estimation technology.

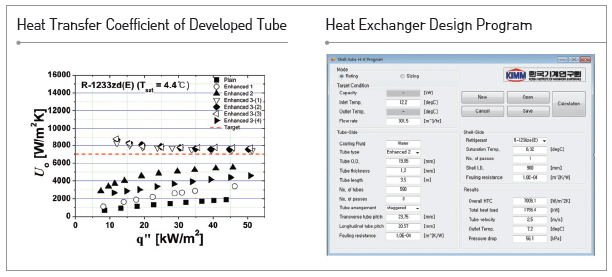

- Development of heat exchanger for centrifugal chiller: Accurate design/manufacturing

technologies are required based on actual heat transfer coefficient.

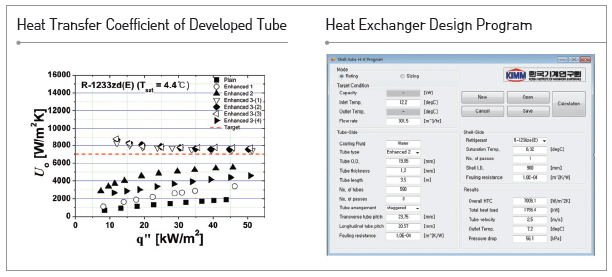

Technical Differentiation

- Development of various refrigeration cycle performance prediction program

including single/double compression cycle using low GWP refrigerant

- Development of centrifugal chiller evaporator design program

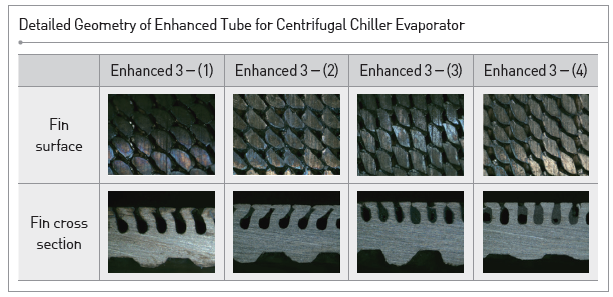

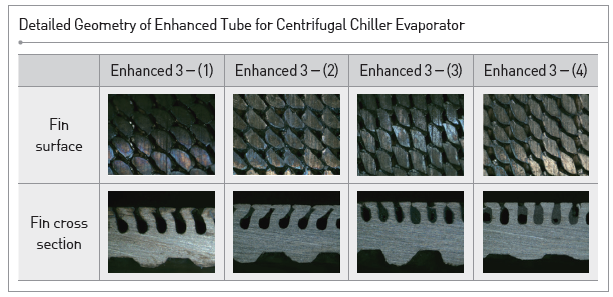

- Development of heat transfer enhanced tube for low GWP refrigerant with similar

performance to those of advanced companies.

Excellence of Technology

- Development of enhanced tube for flooded evaporator for low GWP refrigerant (R-1234ze(E) and R-1233zd(E))

- Similar performance to overseas advanced product, and confirmed the quality of themass production process.

- Centrifugal chiller evaporator design technology development: The prediction of

heat exchanger performance is similar to the level of advanced design program.

Current Intellectual Property Right Status

PATENT

- Industrial Shell & Tube Heat Exchanger Design Program (KR2017-011728)

- Falling Film Type Centrifugal Chiller (KR2017-0053101)

- Falling Film Type Centrifugal Chiller (KR2017-0053100)

KNOW-HOW

- Heat exchanger performance test facility production/operation

- Refrigerant property-based thermodynamics cycle simulation

|