Heat pump technology including the cycle design/analysis, heat

exchanger design/manufacturing, and compressor performance

assessment technology for heat pump system generating high

temperature steam over 120℃

Client / Market

- Existing boiler, heating market and industrial sectors that require high temperature steam, such as drying and food process

Necessity of this Technology

- Generating steam using heat pump instead of conventional boiler to save energy and reduce greenhouse gas emission

- Technology that actively utilize renewable and waste heat of surroundings

- A technology recently commercialized in advanced countries; necessary to develop a very high level technology of world best through active investment and intensive R&D

- Heat energy network technology using high temperature thermal storage-steam heat pump system that resolves the heat energy supply and demand mismatching problem

Technical Differentiation

- Existing heat pump system could be operated to discharge water temperature of 80 to 90℃, but this technology includes design and related technology for generating steam of 120℃ or higher

Excellence of Technology

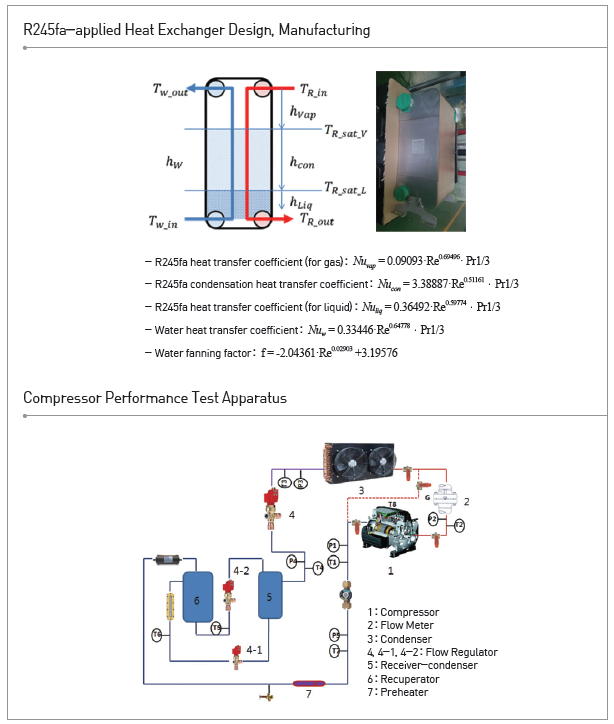

- Design and manufacturing of heat exchanger using new refrigerant (R245fa)

- Development of correlation between sensible and latent heat; design procedure establishment of actual scale heat exchanger

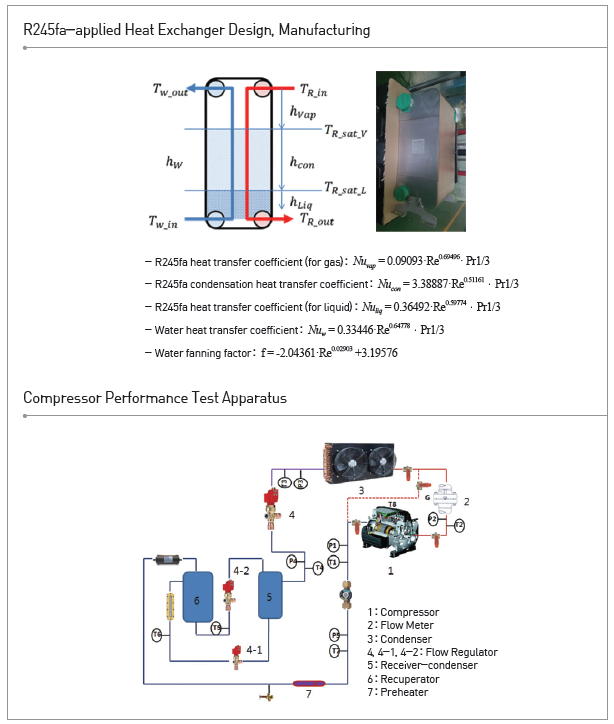

- Development of oil-less refrigerant compressor performance test apparatus for high temperature steam heat pump

- Apparatus for testing performance of oil-less refrigerant compressor such as isentropic efficiency measurement, that using a gas cycle modifying the evaporation and condensation section for reducing the size of equipment

Current Intellectual Property Right Status

KNOW-HOW

- Steam generation heat pump cycle design technology

- Compressor performance and reliability evaluation technology and testing method

- Technology of correlation equation development for design of heat exchanger

|