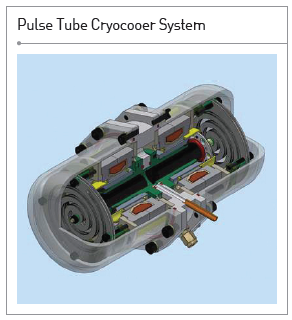

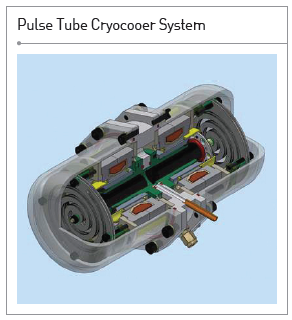

Pulse tube cryocooler technology to make and maintain thermal

environment of extremely low temperature of 120 K (-153℃)

Client / Market

- Transparent electrode, flexible display, TFT backplane manufacturer

Necessity of this Technology

- For a focal plane array infrared detector used for precise thermal diagnosis and

forward observation infrared system, cooling in extremely low temperature is

crucial for clear imaging and high resolution time.

- A high-performance compressor is needed to develop a small size pulse tube

cryocooler with low vibration and high management reliability.

- In particular, development of linear compressor is required in advance, and system

technologies such as optimal function combination of the compressor and the

expander.

Technical Differentiation

- Thermal load issue following high density integration solved

- Contributed to low vibration and miniaturization

- Realized pulse tube cryocooler design and production technology to replace the

Stirling cryocooler

- Overcame limitations regarding size and energy efficiency of cryocooler

- Completed the production of prototype of 100 W linear compressor (Size: diameter

100 mm/length 250 mm)

- Completed making of components like linear motor, cylinder/piston, gas flow line

and prototype

- Verified the components making and assembly symmetry for reducing the vibration

from the counter-direction moving piston

- Proposed the design to reduce the volume of the gas storage by putting the heat

exchanger in the gas storage

Excellence of Technology

- Designed/Produced a coaxial pulse tube expander to replace existing Stirling

cryocooler

- Selected the design that separates the pulse tube and the regenerator to reduce

the loss from temperature difference in the coaxial pulse tube expander, and made

the outer pin on the high temperature part for effective heat transfer of the heat

exchanger

- Improved the cooling speed delay issue by miniaturizing the lower temperature part

of the expander (expander external diameter 15 mm)

- Achieved 70% efficiency of linear compressor and 0.8W (@79.8 K) expander cooling

capacity

CURRENT INTELLECTUAL PROPERTY RIGHT STATUS

PATENT

- Pulse Tube Refrigerator Having Gas Storage Unit to Which Exchanger Is Attached

(KR1421045)

- Heat Exchanger for Pulse Tube Refrigerator and Method for Manufacturing the

Same (KR1517786)

KNOW-HOW

- Liner compressor design technology

- Linear motor electromagnetic field analysis technology

- Flexure spring design/analysis technology

- Pulse tube cryocooler performance test technology

|