Technology to coat functional metal/oxide thin films at low temperature

on high polymer-based substrate surface like flexible display or

polymer membrane

Client / Market

- Flexible display, transparent electrodes, TFT manufacturer, membrane manufacturer,

hydrophilic/waterproof film manufacture

Necessity of this Technology

- Existing ultra-thin film coating technology, such as chemical vapor deposition or

metal sputtering, are performed at high temperature.

- Flexible display, transparent electrodes, and TFT manufacturing uses a flexible

polymer film or glass plate, but polymer or glass plates are relatively vulnerable to

heat that high temperature process cannot be applied. Therefore, a low temperature

process for thin film coating is demanded.

- For a polymer membrane, the issue of permeability reduction occurs due to the

hydrophobicity of the surface. To solve this issue, surface functionalization process

(e.g. the oxygen plasma surface treatment). is used to modify the membrane surface

to the hydrophilic surface.

- However, since oxygen plasma treatment effect decreases with time, surface coating

with a hydrophilic substance is needed to maintain the surface hydrophilic permanently.

Moreover, a low temperature ultra-thin film coating technology is required to avoid the

pore size reduction of polymer membrane during coating process.

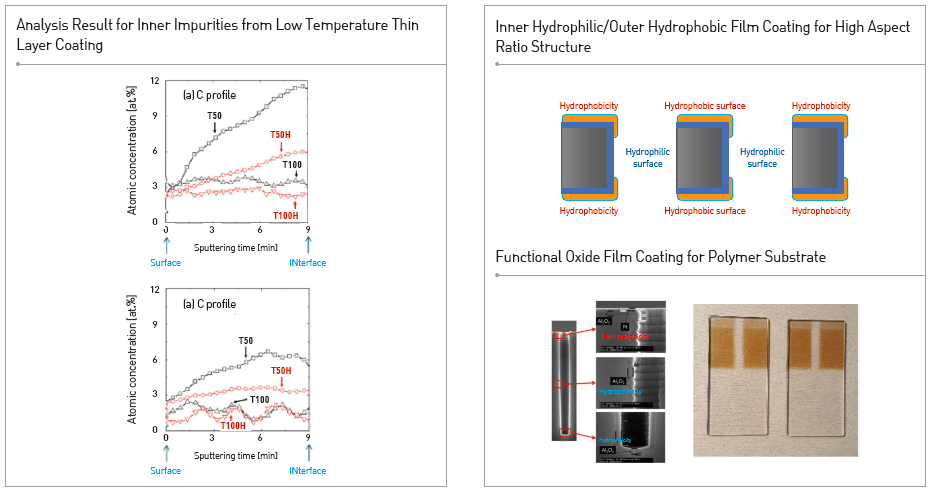

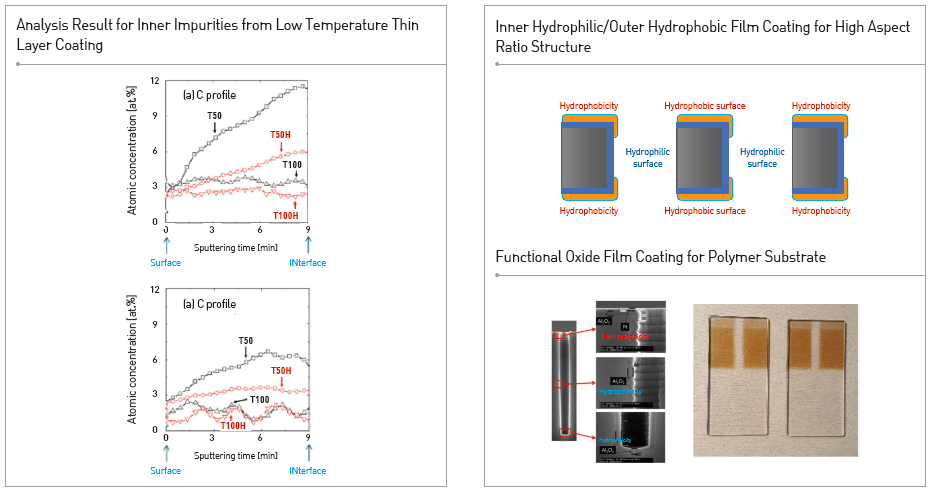

Technical Differentiation

- Ultra-precise control of ultra-thin film thickness with resolution of 0.1 nm is possible

within the temperature range where the polymer substrate is not damaged. (usually

below 150℃)

- Various ultra-thin film coating technologies such as atomic layer deposition (ALD),

chemical vapor deposition (CVD), electron-beam evaporation, and DC/RF sputtering can

be applied according to substrate and required film material and coating thickness.

- Surface functionalization and nanostructure fabrication is capable through

functional metal/oxide thin film coating on the polymer substrate.

Excellence of Technology

- Low temperature and ultra-precise functional metal/oxide film coating technology for

the polymer-based substrates and nanostructure surfaces (coating process temperature

below 150℃, thickness precision level 0.1 nm, thickness uniformity over 95%)

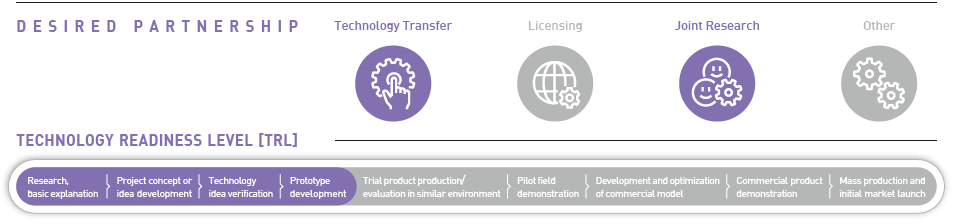

- Various ultra-thin film coating technologies can be integrated to coat functional

substances in/outside of the high aspect ratio/channel structure

- Coating technology for surface functionalization through ultra-thin metal/oxide

films deposition on the polymer substrates and nanostructure surfaces.

Current Intellectual Property Right Status

PATENT

- Photonic Crystal Nano Structure Method for Making the Same (KR1501005)

KNOW-HOW

- Coating a functional ultra-thin film at low temperature without deformation/damage to flexible polymer substrate

- Applying customized ultra-thin film coating technology to suit demanded ultra-thin film material and thickness

- Coating of functional metal/oxide thin film on polymer material surface

|