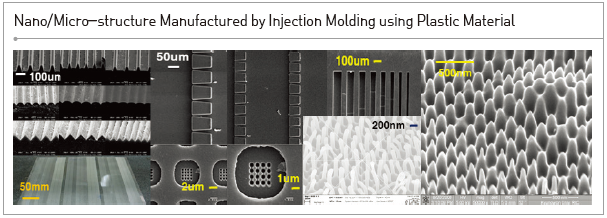

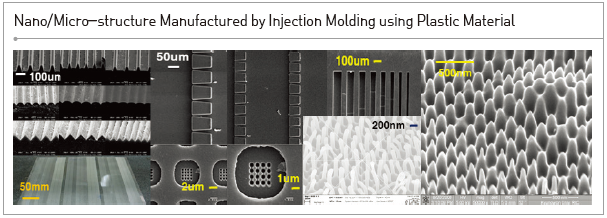

Mold and process technology for injection molding to produce

plastic products with surface nano/micro-structures ranging from dozen nanometers to several hundred micrometers

Rapid heating/cooling mold and process technology to injection

mold precisely nano/microstructures existing on surface of plastic products including demolding of the injection molded surface structures.

Client / Market

- Diagnostic device, medical device company, electrical electronics and home

appliances, automobile and automobile parts, plastic exterior products

Necessity of this Technology

- Nano micro structures are manufactured mainly by etching process for silicon

and glass substrate, hot embossing or PDMS casting as a replication process,

but injection molding process is required for large scale manufacturing of plastic

products with nano/micro surface structures

- During the injection molding of plastic products, plastic melt injected into the

mold cavity is solidified quickly from the surface to cause incomplete replication of

the nano/micro structure on the surface. Another issue is the deformation of the

injection molded surface structures in demolding step due to interference with the

mold surface. These incomplete replication and deformation of the nano/micro

surface structures are main drawbacks for practical use.

- For mass production of plastic products with nano/microstructures, advanced

mold and process technology for injection molding is a key to mold nano/microstructures

precisely while maintaining the productivity and cost competitiveness of

conventional injection molding.

Technical Differentiation

- Equipped for mold technology using metal stamper with surface nano/microstructures

fabricated by lithography and electro-plating process, enabling quick

development of products employing nano/microstructure.

- Injection molding of High aspect ratio nano/microstructures based on rapid heating/

cooling technology for the mold using stamper

- Design of applications employing Nano/microstructure and manufacturing of

prototype based on mass production process

Excellence of Technology

- Manufacturing of plastic products employing surface nano/micro-structures with

the productivity equivalent to that conventional injection molding process (cycle time <1 minute)

- Equipped for injection molding technology in large scale of production for plastic

plates with surface nano/micro-structure such as micro-channel.

- Injection molding technology for High aspect ratio nano-structure

Current Intellectual Property Right Status

PATENT

- Mold for Molding Nano/Micro Surface Structure (KR0768329)

KNOW-HOW

- Mold structure for injection molding using a stamper with surface Nano/microstructure

- Rapid heating/cooling mold and process technology

- Optimization of injection molding technology for plastic plate with surface nano/micro-structure

- Demolding technology of article with surface Nano/micro-structure during the injection molding

|