Technology to manufacture ultra-fine micro/nano pattern metal

core required mandatorily to improve the special functions of

high-performance advanced products based on ultra-precision

machining technologies (turning, planing, end milling, indentation

machining) with nano-level precision.

Client / Market

- Advanced core components market such as optical elements for advanced display

(LCD/LED, OLED, AR/VR) and solar energy, meta structure, hologram, optical lens

and optical communication, high-performance core element for medical/bio and

mechanical component

Necessity of this Technology

- The demand from various advanced industries for high performance ultra-precision

fine patterned components are rapidly increasing. However, the foundation

technologies of ultra-precision machining technology for fine pattern are weak to

effectively handle such demands.

- To achieve with performance advancement of high-quality products and the

demands for high-performance products required for next-generation advanced

industries, a high-efficiency micro-pattern mold core machining technologies

based on ultra-precision machining technology of nano level is required.

Technical Differentiation

- Possible to manufacture various high-quality, high-profile micro-pattern from

a few dozen nanometers to a few hundred micrometers required depending on

properties and functions of core devices.

- Possible to manufacture an ultra-precision micro-pattern mold core to cope

with roll-to-roll process, injection molding, and press forming required for mass

production of high-performance advanced products

- Possible to apply integrated machining technology such as micro/nano complex

shapes and high-dimensional shapes and fabrication of micro-pattern having irregular

shapes and arrangement that can be utilized for next-generation advance industries

Excellence of Technology

- Ultra-precision machining technology on large area micro pattern roll mold for optical film manufacturing.

- The mold core for ultra-precision groove patterns, random stepped profile surface,

lenticular patterns of several dozen nanometer to several dozen micrometer level for

optical film manufacturing

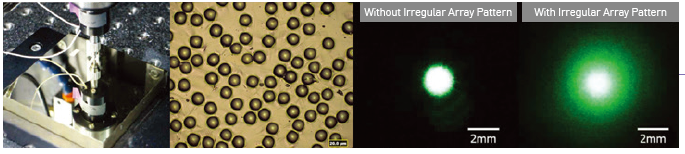

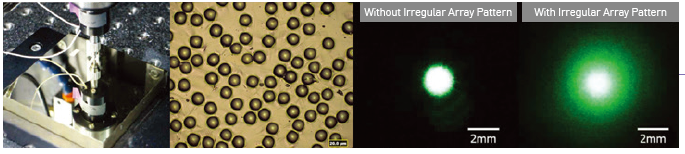

- Ultra-precision indentation machining technology for irregular lens array patterned mold core to improve light diffusion property.

- Irregular lens array machining technology with minimum diameter of 15 μm and maximum fill-factor of 50%

- Light diffusion property improved up to 12 times

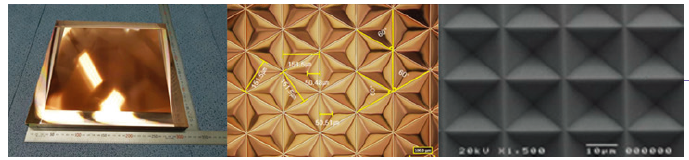

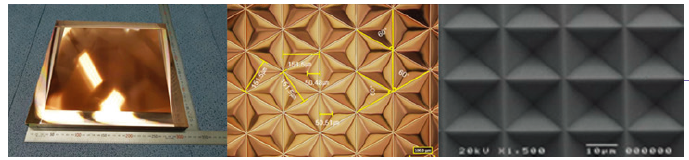

- Ultra-precision cutting technology with 3-directional crossing micro pattern largearea mold core for high-brightness retro-reflection property

- Intersecting point error within 1 μm, pattern shape error within 1 μm

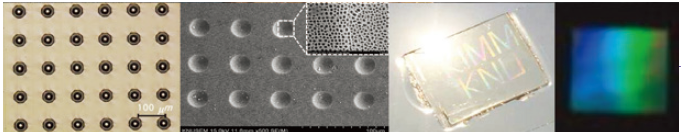

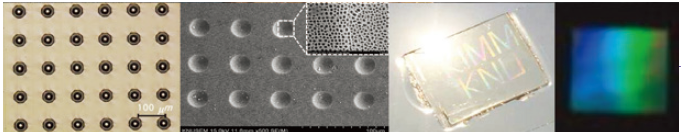

- Mold core machining technology of micro pore lens array pattern for structural color revelation

- Micro/nano patterning technology for structural color revelation using mechanical/chemical integration machining

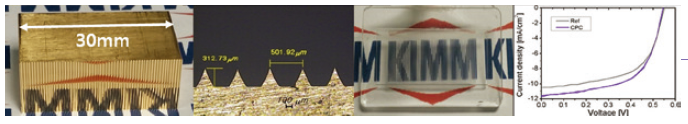

- Array pattern machining technology for aspheric, high aspect ratio paraboloid

condensing lens mold

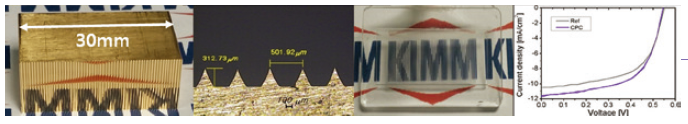

- Solar energy short-circuit current density enhanced by 10% with increased lightharvesting effect

- Ultra-precision machining technology of micro slit array for a meta-surface

- Ultra-precision micro slit array machining with shape error within 1 μm and position error within 1 μm

- Realizing a meta-surface to converts longitudinal wave into transverse wave

- Micro end milling technology of optical patterns for realizing 3D image

Current Intellectual Property Right Status

PATENT

- Processing Method for Aspheric Light Guide Plate Mold (KR1630021)

- Method for Manufacturing Working Tool of Mold for Manufacturing Optical Film

(KR1767311)

- Method for Designing Random Dot Pattern and Method for Manufacturing Lens

Array Member (KR2017-0142784)

- Micro Pattern Machining Method Using Tool Angle Control (KR1474974)

KNOW-HOW

- Pattern forming roll machining system and micro pattern formation method

- Discontinuous micro pattern formation device using indenter and the method

- Micro wave pattern machining system and method

- Stepped shape, right/left or top/bottom direction micro pattern design and machining technology

- Cutting tool design technology for micro pattern machining/measurement analysis and performance evaluation technology of micro pattern

|