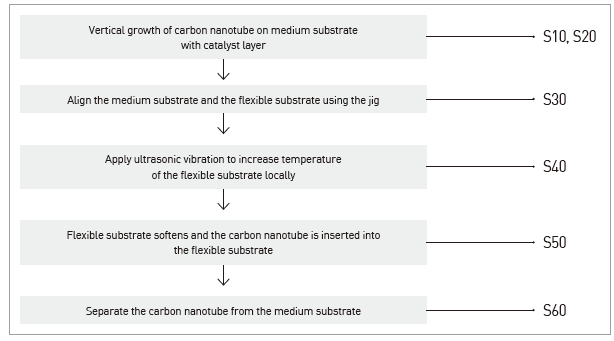

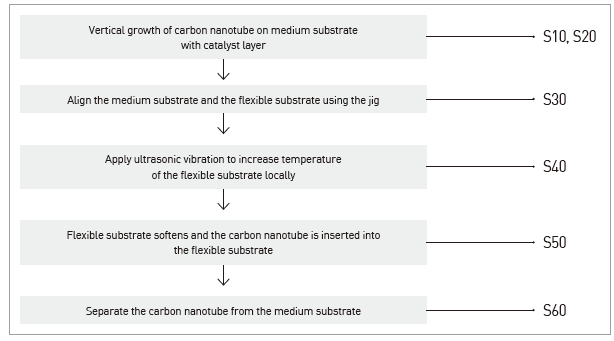

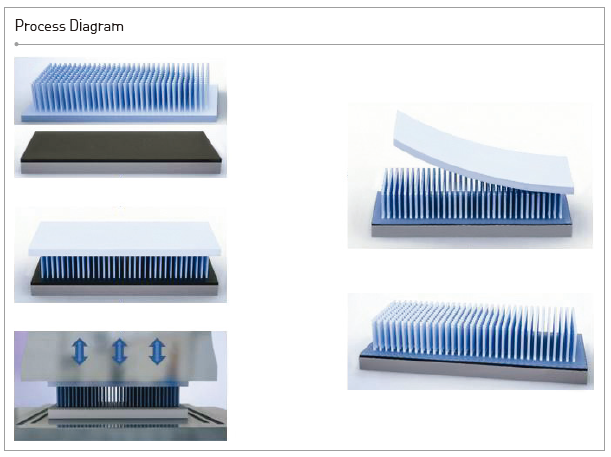

Flexible carbon nanotube emitter manufacturing technology that

combines the flexible substrate and the carbon nanotube by locally

increasing the temperature of the area where the flexible substrate

and the carbon nanotube are in contact

Client / Market

- Transparent electrode, flexible display, TFT backplane manufacturer

Necessity of this Technology

- Existing method of manufacturing a carbon nanotube emitter on a flexible substrate

used a spray coating or ink jet printing to coat the carbon nanotube on the substrate,

but the electrical contact between the flexible substrate and the carbon nanotube is

poor, and this decreases the emitter performance and generates a lot of heat.

Technical Differentiation

- It forms a strong mechanical bond between the carbon nanotube and the flexible

substrate.

- By locally increasing the temperature at the area where the flexible substrate and

the carbon nanotube are in contact, the thermal deformation of flexible substrate is

prevented.

- The electrical contact between the flexible substrate and the carbon nanotube is great.

- Since it is unnecessary to heat the entire flexible substrate for bonding the substrate

with the nanotube, thermal deformation of the flexible substrate is prevented.

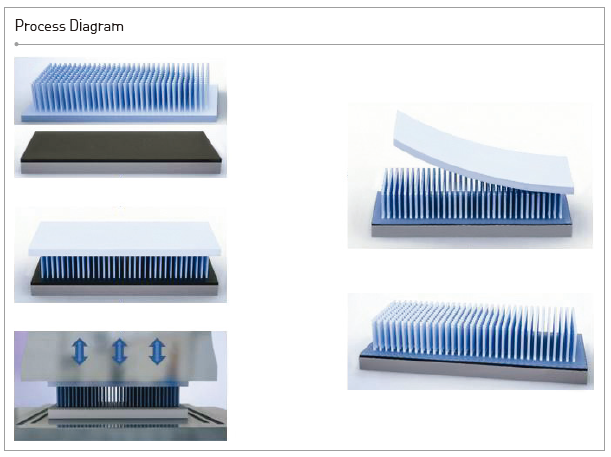

Excellence of Technology

- The carbon nanotube is vertically grown on the medium substrate.

- The flexible substrate is aligned to face above medium substrate while being in

contact with the carbon nanotube.

- Above medium substrate is vibrated while the contact between the carbon nanotube

and above flexible substrate is maintained.

- The part of the flexible substrate touching the carbon nanotube softens, and above

carbon nanotube is inserted into the flexible substrate.

- The medium substrate is separated from the carbon nanotube.

Current Intellectual Property Right Status

PATENT

- Flexible Carbon Nanotube Emitter Manufacturing Method and Flexible Carbon

Nanotube Emitter Made with Above Method (KR1029566)

|