Interconnection/stacking technology for ultra-thin flexible

semiconductor package with flexible substrate using polymer

elastic bump, neutral plane design for package

Client / Market

- Semiconductor manufacturer (Foundry, OSAT (Outsourced Semiconductor Assembly and Test))

- Display manufacturer

Necessity of this Technology

- Along with development of wearable device performance and rapid growth of its

market, the need for ultra-thin, high-performance, high-flexibility, and humanfriendly

flexible semiconductor package has increased.

- To create a flexible semiconductor package, a thin silicon chip with the thickness

between 20 to 50 μm needs to be bonded on a flexible substrate.

- Conventional bonding process using solder bump to bond the chip under high

temperature has a problem of flexible substrate damage and thin silicon chip

damage due to thermal stress.

With another bonding technology, a rigid metal bump can be bonded with a pad

using NCF adhesive, however, it leads to issues such as chip damage due to

stress concentration caused by uneven bump height, joint coming off due to NCF

shrinkage, and declined flexibility due to hard joint.

Technical Differentiation

- This technology uses the wafer transfer technology to design the neutral plane for

the chip to minimize stress while bending and make handling chip during bonding

easy to enable production of ultra-thin flexible silicon chip that is thinner and more

flexible than the conventional chip.

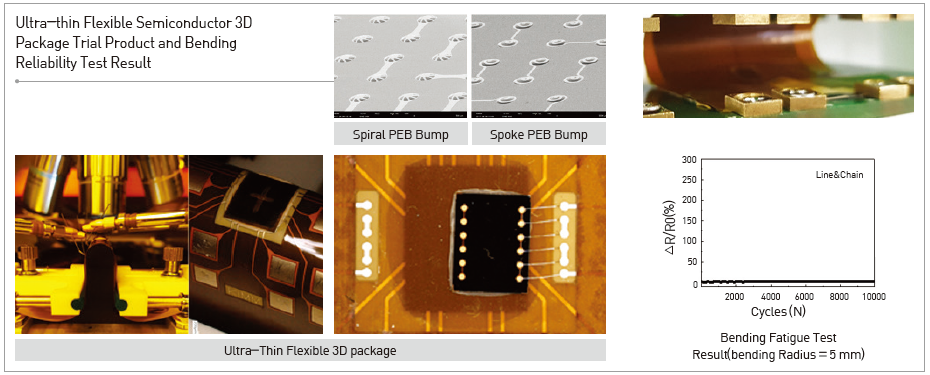

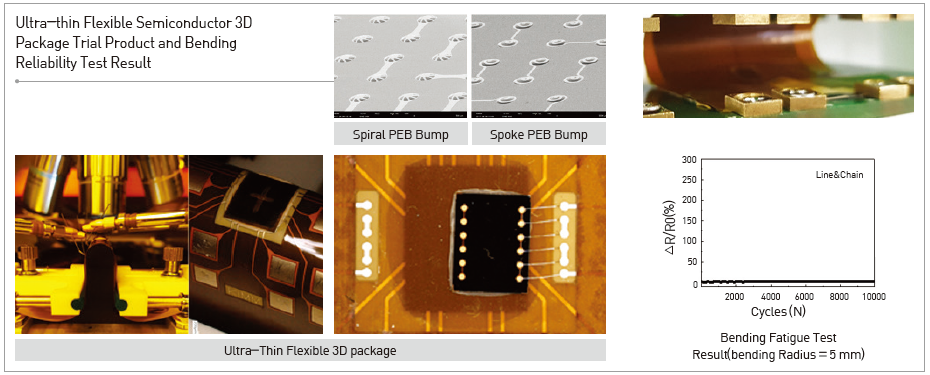

- By applying the polymer elastic bump structure, which boasts easier elastic

deformation and restoration, for the thin flexible silicon chip, damage to the thin

flexible chip from uneven bump height during chip bonding is minimized with the

elastic deformation and stress relaxation.

- Also, this bonding technology has excellent reliability and low contact resistance as

the contact between the bump and the pad is maintained with the elastic restoration

even when the adhesive shrinks. With the flexible bonding interface composed

of polymer bump and adhesive, this technology is able to realize higher flexibility

compared to conventional bonding technology.

Excellence of Technology

- With wafer transfer technology, neutral plane for chip/package is designed to allow

handling and bonding of thin flexible chip with thickness less than 10 μm without damage.

- By applying the polymer elastic bump structure that boasts easy elastic deformation

and restoration to thin flexible silicon chip, a flexible semiconductor package with

bending radius of 5 mm and bending fatigue of over 10,000 cycles was created.

- Using the bonding technology above, the 3D ultra-thin flexible semiconductor

package trial product was manufactured to prove the technology.

Current Intellectual Property Right Status

PATENT

- Face-down Type Flexible Electronic Device Manufacturing Method and Flexible

Electronic Device Manufactured Using the Method (KR1511023)

KNOW-HOW

- Polymer elastic bump fabrication technology

- Flexible chip neutral plane design and thinning technology

- Thin wafer transfer technology for neutral plane design

- Flexible semiconductor package 3D stacking and low-temperature bonding technology

|