Surface texturing applied on key components in the eco/bio industry

or product and technology for surface texturing application

Client / Market

- Friction reduction transportation field, machine lubrication field, Solar cell

luminance efficiency improvement field, hospital’s anti-virus biofilm and selfcleaning

field, display industry

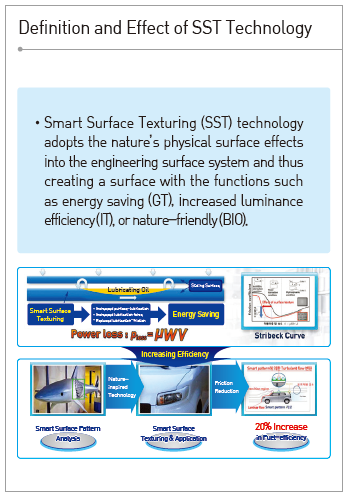

Necessity of this Technology

- Relying on the shape and material of components processed using existing technology

has limits regarding friction reduction and pro-/anti-cell increase technology, and

to create a surface with additional function, smart surface texturing technology with

surface pattern with the size up to several hundred microns needs to be applied.

- Relying on the shape and material of existing components has limits regarding

friction reduction and pro-/anti-cell increase technology-this technology can be

considered very original as it is an eco-friendly process-based high-precision

machining technology that replaces existing chemical etching or MEMS method.

- Need friction reduction, pro-cell functional effect realization, and various converged

machining

Technical Differentiation

- Using a component with fine patterns created on the surface, a functional

component can be created. Obtainable effects include friction reduction, cell and

virus-related characteristics improvement, and enhancement of optical function.

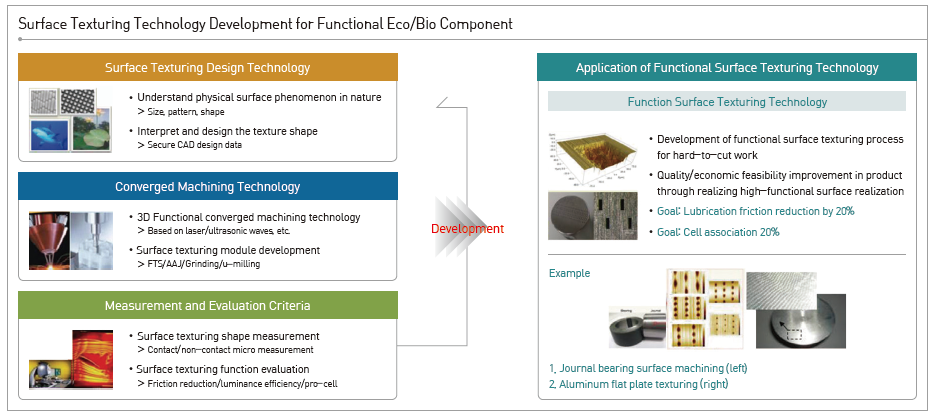

- Analyzing and simulating the smart textured surface in nature require pattern

shape measuring technology, computer simulation technology to copy the pattern

and estimate the function of the pattern, high-precision machining and control

technology to process pattern, and chemical process for post-processing of

surface; its technological ripple effect throughout the field of engineering is great.

- Based on realization of the eco-friendly method, this technology grants detailed

surface texturing using a method other than chemical treatment-partially applied

in the industry, and in particular, the technology goes beyond the limitations of

material as it can even be applied on metal surface.

- This technology includes technologies for various ripple effects regarding surface texturing

module, applicable eco/bio-related products, and machine for module application.

- As machining realizes uniform function, it is favorable for creating consistency in

function between products.

Excellence of Technology

- For dimple and riblet machining, lubrication friction and air/fluid friction is reduced

by up to 8 to 10%, which has been proven with theory and experiment.

- High-precision machining method for surface texturing can be directly applied on

hard material.

- Surface texturing shape research, machining process development and shape

measurement/function evaluation technology is a leading advanced technology

growing globally.

- Has 3 international patents and 34 other patents Received multiple awards including

Award Certificate of Director of Patent and Trademark Office (No. 7487, 2009) and

Order of Science and Technological Merit (Jinbo Medal) (No. 94, 2011)

Current Intellectual Property Right Status

PATENT

- Bearing device using Magnetorheological Elastomer (KR1334389)

- Grinding Apparatus for Surface Texturing and the Grinding Method Thereof (KR1400876)

- Optical Head for Machining Cone Shape and the Laser Processing Apparatus Using Thereof (KR1373839)

- Optical Head for Vertical Cutting and Laser Processing Apparatus Using Thereof (KR1373836)

- Abrasive Air Jet Machining Apparatus Capable of Optical Measurement (KR1334388)

- Abrasive Air Jet Machining Apparatus with A Function of Heat Treatment (KR1334387)

- Abrasive Air Jet Machining Apparatus Having Multioutlet Nozzle (KR1334386)

|