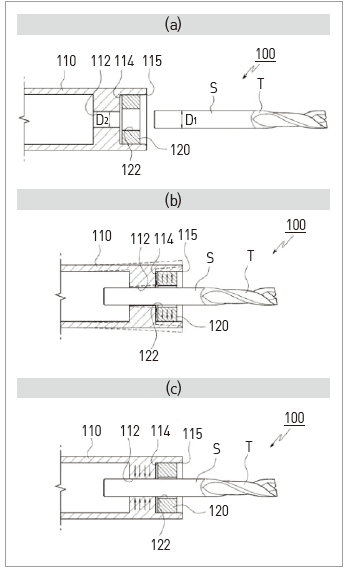

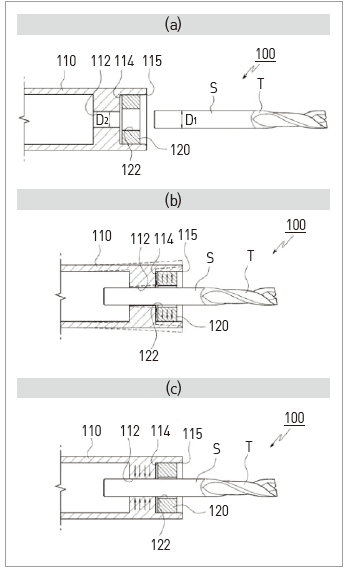

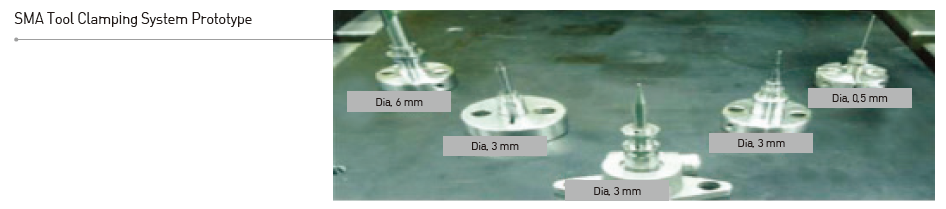

Miniaturization applying shape memory alloy; Micro tool clamping

device and grinding tool holder, etc. using shape memory allow with

high rotation precision during high-speed rotation

Client / Market

- Tool market, cylindrical product clamping field

Necessity of this Technology

- Need for simple structure and reduced tool changing time

- Existing taper collet-chuck method made the entire design of the tool holder

complex; accumulating taper collet geometric errors increase the geometric tool

setup errors

- Shrink-fit method requires changing tools by moving to a separate hightemperature

heating system, which complicates the system configuration and adds

extra expenses.

- Need to reduce the number of tools for a small tool holder device and miniaturize

with a compact design

- Increased demand for tool holder and tool holding method using shape memory

alloy that would shorten the tool changing time

Technical Differentiation

- Simple structure with steel holder and SMA ring

- Only requires a simple additional facility of a spray type cooling device for cooling to

0 to 30 degrees

- Huge reduction in tool changing time as a result of small temperature difference

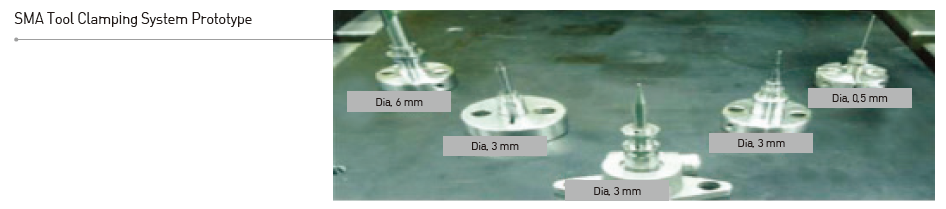

- Miniaturization realized by reducing the number of clamping device components

with shape memory alloy

- Minimized mass imbalance factors with the axially symmetric clamping design to

improve rotation precision

- Structurally reduced the number of components in the tool holder reduces

accumulated tolerance and realizes high-precision operation

Excellence of Technology

- The market demand is huge with approximately 60 special steel tool manufacturers,

60 hard metal tool manufacturers, and 50 diamond tool manufactures only in Japan.

- The annual U.S. tool market sales reach 65 billion dollars, and as the market

focuses on cutting cost, the need for developing low-cost high-efficiency grinding

tool technology has increased.

- This technology realizes compact design and shortened tool changing time and

satisfies the market’s demand.

- Has 3 international patents and 34 other patents

- Received multiple awards including Award Certificate of Director of Patent and

Trademark Office (No. 4778, 2009) and Order of Science and Technological Merit

(Jinbo Medal) (No. 94, 2011)

Current Intellectual Property Right Status

PATENT

- Tool Change Apparatus and Tool Change Method of Tool Holder Using Shape

Memory Alloy (KR105527)

- A Fixture System For machine tools Using A Shape Memory Alloy (KR0987814)

- Tool Holder Using Shape Memory Alloy and Tool Holding Method (KR1136382 PCT/

KR2010/008768 13/509135)

- Collet Chuck Using Shape Memory Alloy (KR1144617)

- A Cutting Tool Holder Using Shape Memory Alloy (KR1136381)

- A Cutting Tool Holder Using Shape Memory Alloy (KR1117579)

- Tool Holder Using Shape Memory Alloy (KR2014-0035057)

- Cutting Insert Holder Using Shape Memory (KR1117580)

- Spindle-tool Assembly Using Shape Memory Alloy and Machine Tool Having the

Same (KR1284286)

|