Developing a new concept for High device performance/high flexibility

The formation of Fine metal patterns(≤100 μm)for FHE(flexible

hybrid electronics) and the fabrication of 3D step height metal

interconnection

DI(direct imaging) technology for creating non-damaging fine

pattern(≦100 μm)/pitch(≦20 μm) for stretchable device and display

Client / Market

- Technical field for FHE (flexible hybrid electronics)

- Technical field for DI (direct imaging) fine pattern/pitch formation for non-damaging

flexible/stretchable display areas

Necessity of this Technology

- When using existing mass production MEMS Fab. process/equipment, the process

cannot be performed if there is step height (≧5 μm) between the substrate and the

thin chip (equipment / process compatibility issue).

- n forming 3D interconnection, wire-bonding creates mechanical damage of less

than 50 μm to the thin chip due to heat, pressure, and ultrasonic energy.

- Absence of face-up 3D metal interconnection technology to fabricate fine pattern (≦

100 μm) pitch (≦20 μm)

- Absence of technology that can form flexible/stretchable pattern without damaging

low Tg flexible/stretchable substrate (wiring printing and sintering technology)

- Therefore, to overcome such problems, it is necessary to develop DI type nondamaging

fine pattern/pitch creation technology.

Technical Differentiation

- Technology to effectively form 3D interconnection masklessly without causing

mechanical damage to the thin chip with thickness below 50 μm mounted on the

flexible/stretchable substrate

- Technology to create fine pattern (≦100 μm)/pitch (≦20 μm) with the DI (direct

imaging) method

- Technology to sinter ink material on the flexible/stretchable substrate without

thermal damage

- Technology for intrinsically/geometrically robust metal pattern formation for

stretchable display

- Technology to rework and repair for mass production yield improvement

Excellence of Technology

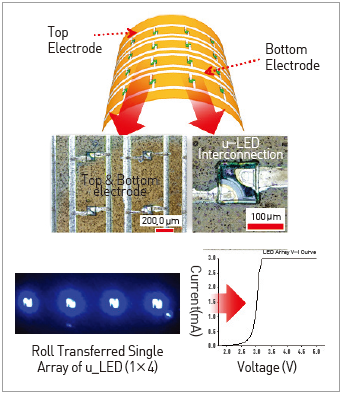

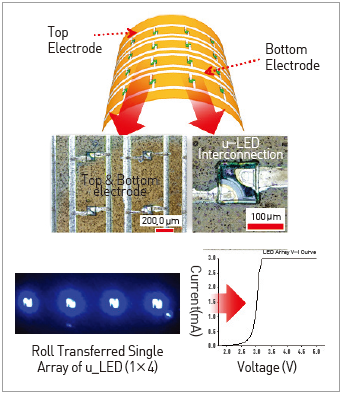

- Formation of 100 μm×100 μm (thickness≈5 μm) micro-LED top & bottom electrodes

and securing face-up 3D metal interconnection (line width ≦ 30 μm)

- Securing DI micro metal pattern method when line width is below 10 μm

- Establishment of database by ink material for overcoming 3D step height in the flat (0 μm)

to 50 μm area

- Securing sample production technology for micro step height (flat (0 μm) to 50 μm)

control for DI process and ink property evaluation

- Performance of laser sintering test for non-damaging ink sintering on polymer

substrate

Current Intellectual Property Right Status

PATENT

- Wearable Dry Patch Type Hybrid Substrate and Manufacturing Method (KR1756847)

- Non-penetrating, Superhydrophobic Polyimide Film Manufacturing Method

(KR1641207)

- Elastic Device Manufacturing Method and Elastic Device Manufactured with the

Method (KR2017-0133265)

- Electrode Pattern Formation Using Laser Sintering and Electrode Pattern Formation

System for the Method (KR2017-0060814)

KNOW-HOW

- Non-damaging, DI fine pattern/pitch formation technology

- Face-up 3D step-covered metal interconnection technology

- Intrinsically/geometrically flexible or stretchable metal formation technology

- Repair and maskless process technology for yield improvement

|