Laser machining device for easy control of laser beam focus

Groove machining method for adjustment of tilt angle using laser

Client / Market

- Laser machining device

- Companies with demand for high aspect ratio drilling technology

(e.g. engine nozzle manufacturer, etc.)

Necessity of this Technology

- Existing mechanical drilling has an issue of the high strength material easily

breaking during drilling.

- Existing laser drilling adjusts the gaussian distribution of the beam strength to

control the groove angle.

- In this case, the groove angle cannot be controlled precisely.

- With existing laser drilling, the laser beam or material can be tilted to adjust the

angle, but in this case, the large device has to be adjusted, therefore precise angle

change in micro units is difficult. Also, with the angle change, the reference point

of the device changes, which also changes the focus and decreases the machining

precision.

- The price for purchasing Germany’s Trepanning laser product is considerably high.

Technical Differentiation

- Overcame the limitations of existing laser drilling

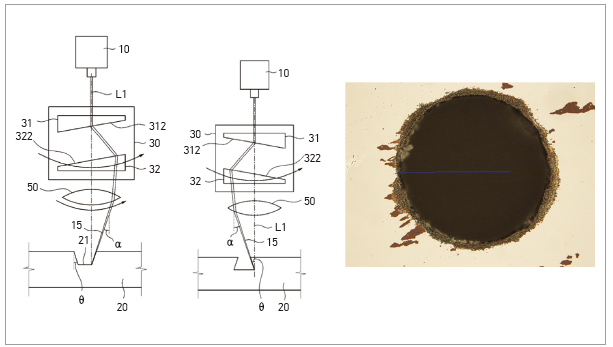

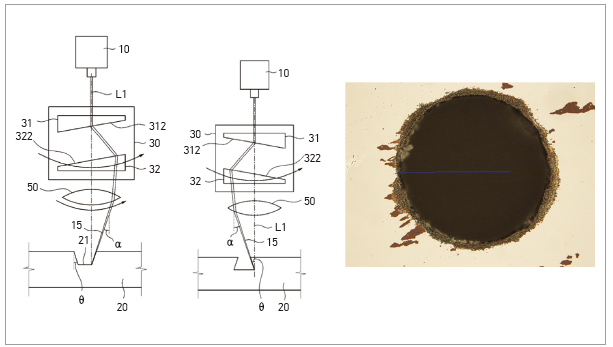

- The side tilt angle of groove can be adjusted through the axial precession using

trepanning optics, which allows precise and easy side tilt adjustment.

- By rotating polarized light of laser beam, the processing speed and efficiency is improved.

- Miniaturized optical system

- Can be supplied at a lower price compared to existing trepanning laser products

Excellence of Technology

- Possible to perform high aspect ratio drilling–hole depth less than 5 mm and diameter over 10 μm

- Possible to process grooves in various forms

- Possible to process grooves in a difficult shape that cannot be processed with existing drilling technology

- Possible to easily adjust the groove’s side angle

Current Intellectual Property Right Status

PATENT

- Groove Machining Method for Tilt Angle Adjustment Using Laser (KR1269835)

|