- Created2022.02.22

KIMM Develops a System that Simultaneously Reduces PM and NOx Emitted from Port Handling Machinery

- Optimized system for port handling machinery, KIMM’s new technology removes up to 80% of fine particle emissions -

For the first time in Korea, in an effort to reduce fine particles emitted from port handling machinery, the Korea Institute of Machinery and Materials (President Sang Jin Park, hereafter referred to as KIMM), an institute under the jurisdiction of the Ministry of Science and ICT, has developed a system that simultaneously reduces PM1) and NOx2) emissions and succeeded in a field demonstration at the Port of Busan.

1) PM: Particulate Matter

2) NOx: Nitrogen Oxide

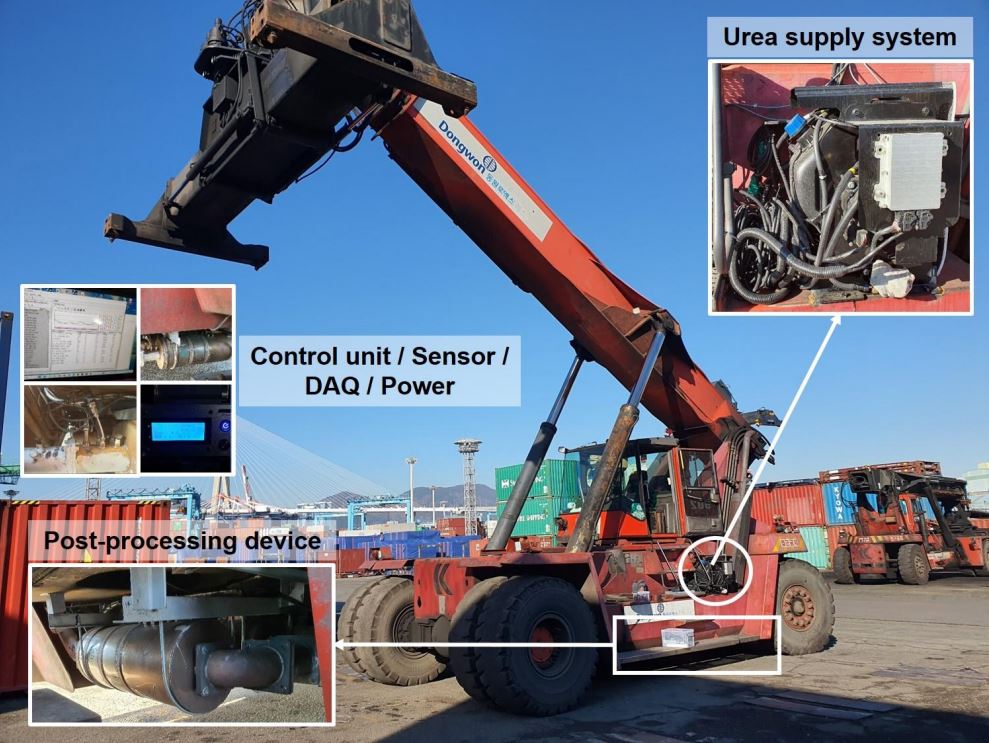

Dr. Gyu Baek Cho, Director of the Busan Machinery Research Center at KIMM, developed a simultaneous PM and NOx purification system, which has DPF3) and SCR4) system installed, optimized for the reach stackers in operation at the ports. To improve the efficiency in fine particle removal, SiC5) and metal catalyst supports6), low-temperature SCR catalysts, urea solution supply devices, and ammonia slip control technology were applied.

3) DPF: Diesel Particulate Filtertrap

4) SCR: Selective Catalytic Reduction

5) SiC: Silicon Carbide

6) Catalyst support: material that physically supports catalysts

For this project, the KIMM research team tested the system for 3 months (from December 2021 to February 2022) on loading and unloading vehicle ‘reach stacker’ at the Busan Container Terminal, operated by the Dongwon Loex Inc. As the results of the demonstration, the KIMM research team confirmed that 80% or more of fine particle, both PM and NOx, was reduced. OBD7) function and integrated control unit were developed together with the system, further enhancing the usability and safety.

7) OBD: On Board Diagnosis, self-diagnosing

Most of the reach stackers that are currently in operation were introduced before the Special Act on Port Fine Particle Management was implemented, and thus they do not have emission reduction system. PM and NOx generated from reach stackers are about 4~5% of the total amount of fine particle pollution generated by the port handling machinery at Busan Port.

To handle this issue, Government, Busan City, and pier operators are offering their support for researches and demonstrations of new technologies developed to resolve the air pollution problem.

The KIMM research team plans to continue on the follow-up research and demonstration in developing the integrated system for both DPF and SCR. Furthermore, the team will work on the optimization of the device so that the device can be applied to other existing reach stackers as well.

Dr. Cho mentioned that the successful development and demonstration of these fine particle reduction system for old port handling machinery is expected to accelerate the establishment of policies aimed at improving air quality. He also added that his goal is to help strengthen the competitiveness of companies working in the field of eco-conscious automobile technology.

[List of Attachments] - Attachment 1: Demonstration of Fine Particle Reduction Technology in Port Handling Machinery (Photo)

The Korea Institute of Machinery and Materials (KIMM) is a non-profit governmentfunded research institute under the Ministry of Science and ICT. Since its foundation in 1976, KIMM is contributing to economic growth of the nation by performing R&D on key technologies in machinery and materials, conducting reliability test evaluation, and commercializing the developed products and technologies.

This research project was conducted with support from the Ministry of Environment’s project for addressing blind spots in fine particle policy and demonstrating reduction efforts, or the “development and demonstration of SDPF for the simultaneous reduction of PM and NOx in small and medium-sized port handling machinery.”

Before this project, the team signed a standard technology development agreement with the Busan Port Authority in 2020, and received necessary testbed for developing and demonstrating the simultaneous PM and NOx purification system.

Credit : The Korea Institute of Machinery and Materials (KIMM)

Usage Restrictions of Multimedia (Attachment File) : The sources of photos and research results from KIMM must be specified.

- Attachment 1: Demonstration of Fine Particle Reduction Technology in Port Handling Machinery (Photo)

Description: Dr. Gyu Baek Cho, Director of Busan Machinery Research Center, has developed a device that simultaneously reduces PM and NOx emissions, with the goal of reducing fine particle caused by port handling machinery. This new technology was applied to port handling vehicles at the Port of Busan for three months, resulting in up to an 80% reduction in fine particle emission.