- Created2021.06.03

Technology developed for equipment used to inspect defects in large-scale display

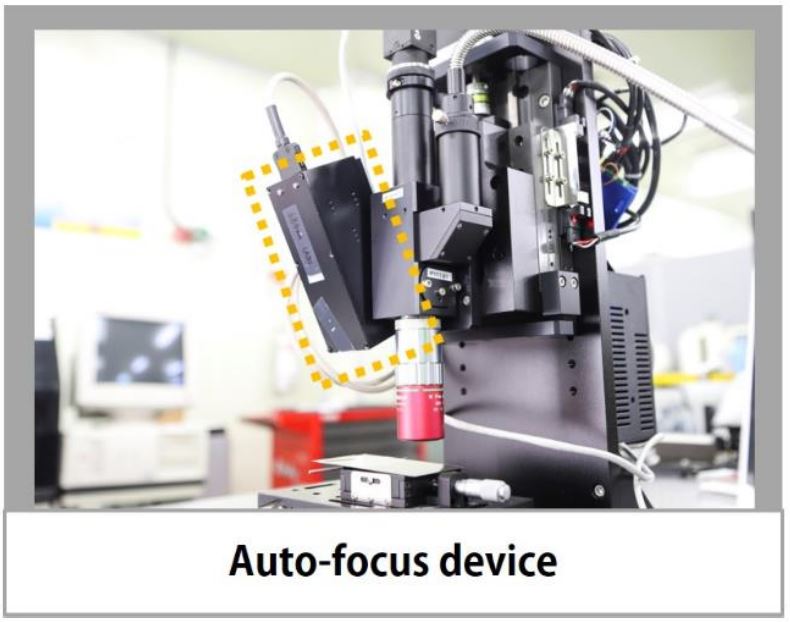

-KIMM succeeds in production of auto-focusing equipment for microscopes and laser processors-

-Technology supports precise, rapid focusing in displays and semiconductors-

The Korea Institute of Machinery & Materials (hereinafter KIMM; President Sang Jin Park) under the Ministry of Science and ICT succeeded in the domestic production of auto-focusing equipment for microscopes and laser processers, thereby reducing dependency on imports.

Dr. Jiwhan Noh, principal researcher of the Department of Laser & Electron Beam Technologies at KIMM, achieved the production of auto-focusing equipment for highresolution microscopes, which are essential for the inspection of defects during display manufacturing.

The auto-focus function focuses on the target, similar to how a camera focuses on a subject. The ability to quickly focus even as the target changes is integral to obtaining clear images.

The team developed a laser semicircular masking displacement technique that allows rapid, precise measurement of differences arising from the movement of displays by applying a semicircle-shaped mask to microscopes used for large-scale display defect inspection.

When a semicircular mask is applied, the laser beam becomes clear and distinct if focusing is accurate, and changes into a semicircular shape if the target is out of focus. The device is able to rapidly refocus as the distance of the subject from the focusing point can be easily determined.

Dr. Jiwhan Noh, principal researcher of KIMM, said, “Auto-focusing equipment for microscopes and laser processors is widely used in the display industry, a key business area of major Korean companies, but so far the field has relied fully on imports. By enabling the production of such equipment, our study will significantly enhance the competitiveness of local businesses.”

[List of Attachments] - Attachment 1: Auto-focus device developed by KIMM (photo)

The Korea Institute of Machinery and Materials(KIMM)is a non-profit government-funded research institute under the Ministry of Science and ICT. Since its foundation in 1976, KIMM iscontributingto economic growth of the nation by performing R&D on key technologies in machinery and materials, conducting reliability test evaluation, and commercializing the developed products and technologies.

The study was conducted using a grant from the Korea Evaluation Institute of Industrial Technology as part ofa project titled“Empirical Study on Laser Technology and Equipment for Ultrathin Wafer Dicing”(principal investigator: Sanghoon Ahn, principal researcher, KIMM).

Credit : The Korea Institute of Machinery and Materials (KIMM)

Usage Restrictions of Multimedia (Attachment File) : The sources of photos and research results from KIMM must be specified.

-Attachment 1: Auto-focus devicedeveloped by KIMM(photo)

Photo description: The auto-focusing optical module produced using technology developed by the team led by Dr. Jiwhan Noh, principal researcher of the Department of Laser & Electron Beam Technologies at KIMM. The team applied a semicircular mask to a laser beam for easier and faster measurement of the target’s distance from the focusing point.