- Created2021.05.31

Metamaterial improves sensitivity of infrared absorption spectroscopy100 times

-KIMM and UNIST develop metamaterial that improves infrared spectroscopic detection signal 100 times-

-Low-cost technique revolutionizes detection of harmful substances and biomolecules-

A local research team, comprised of members of the Korea Institute of Machinery & Materials (hereinafter KIMM; President Sang Jin Park)under the Ministry of Science and ICT andUNIST(PresidentYonghoon Lee),developed a metamaterial absorber that significantly enhances the detection of harmful substances or biomolecules, and published their results in Small Methods.

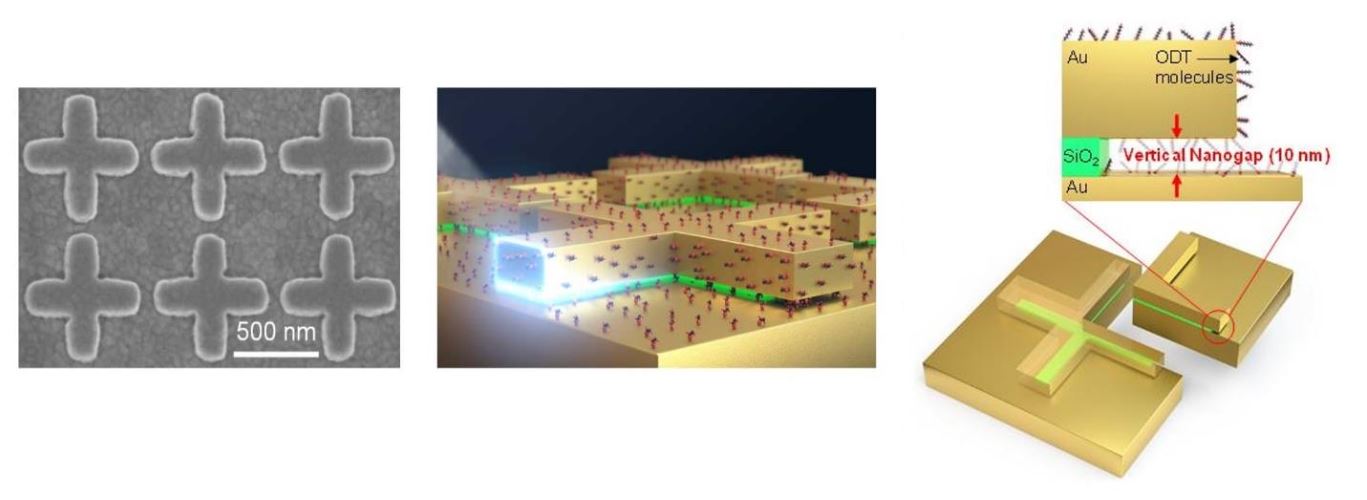

The joint research team led by Principal Researcher Dr. Joo-Yun Jung of the Nano-Convergence Mechanical Systems Research Divisionat KIMM and Professor Jongwon Lee of UNISTdeveloped a metamaterial that enhances infrared absorption spectroscopy through 100-fold amplification of detection signals. The proposed metamaterial is a special functional material with vertical nanogaps of a smaller size than infrared wavelength.

Infrared spectroscopy is a technique that identifies components based on patterns of reflected light by measuring the properties of molecules to absorb infrared of their intrinsic frequencies. If only small traces of the target substance are detected, the results will not be as significant due to the small difference in light intensity.

The proposed metamaterial gathersand releaseslight energy at once, thereby inducing a larger intensity of light that can be absorbed by molecules. The amplified signalsallow more distinct results to be obtained even when working with small tracesof substances.

Cross-shaped nanoantennas were formed in a metal-insulator-metal configuration. The middle insulating layer had a thickness of 10 nm;vertical gaps were employed to maximize light absorption by molecules.

Inyong Hwang, a researcher of the Department of Electrical Engineering at UNIST, said,“The proposed metamaterial achieved a record-high difference of 36% in our demonstration on a monolayer with a thickness of 2.8 nm. This is the best record achieved to date among monolayer detection experiments.”

Dr. Joo-Yun Jung, principal researcher of KIMM, said,“Using the nanoimprint process, we can obtain metamaterials in the metal-insulator-metal configuration, and process them into desired patterns. On top of that, the dry etching process allows mass production of microstructured metamaterials."

Professor Jongwon Lee of UNIST said,“Our study is the first to induce near-field enhancement and resolve near-field exposure using vertical gaps. The technique is expected to have vast applications, especially for infrared sensorsused in the detection of biomolecules, harmful substances, and gases.”

[List of Attachments] - Attachment 1:SEM images of the metamaterial absorber and schematic of the microstructural model(figures)

- Attachment 2: Results of infrared spectroscopic analysis(figures)

The Korea Institute of Machinery and Materials(KIMM)is a non-profit government-funded research institute under the Ministry of Science and ICT. Since its foundation in 1976, KIMM iscontributingto economic growth of the nation by performing R&D on key technologies in machinery and materials, conducting reliability test evaluation, and commercializing the developed products and technologies.

Theresearchresults were published in Small Methods, an international journal published by Wiley, on May 13, with the title “Ultrasensitive Molecule Detection Based on Infrared Metamaterial Absorber with Vertical Nanogap”. The study was conducted with the support of the Global Frontier Center for Advanced Meta-Materials under the Ministry of Science and ICT, and the Nano-Material Technology Development ProgramandCivilian-Military Technology Development Programof the National Research Foundation of Korea.

Credit : The Korea Institute of Machinery and Materials (KIMM)

Usage Restrictions of Multimedia (Attachment File) : The sources of photos and research results from KIMM must be specified.

-Attachment 1: SEM images of the metamaterial absorber and schematic of the microstructural model (figures)

Figuredescription:

Left) SEM image of the metamaterial absorber developed by KIMM and UNIST. Top view shows cross-shaped antenna.

Center) Side view of the microstructure of the metamaterial absorber developed by KIMM and UNIST.

Right) Structure of the metamaterial absorber developed by KIMM and UNIST. Figure shows 10 nm vertical nanogaps.Right) Structure of the metamaterial absorber developed by KIMM and UNIST. Figure shows 10 nm vertical nanogaps.