- Created2023.01.12

KIMM develops Korea’s first smart intraocular lens technology, capable of early-stage dementia diagnosis

- Newly developed smart intraocular lens is inserted into the eye to detect biomarkers for Alzheimer's disease -

- Expected to facilitate early diagnosis of various neurological diseases, such as degenerative brain diseases -

A smart intraocular lens that can be inserted into the eye to diagnose Alzheimer's has been developed for the first time in Korea.

The Korea Institute of Machinery and Materials (President Sang-jin Park, hereinafter referred to as KIMM), an institute under the jurisdiction of the Ministry of Science and ICT, through joint research with Yonsei University, Yonsei University College of Medicine Yongin Severance Hospital, and Gangnam Severance Hospital, has succeeded in developing an intraocular implant that can diagnose Alzheimer's, a degenerative brain disease, at its early stages. The results of this research study were published in Bioactive Materials (IF: 16.874)*, a well-known journal in the field of biomaterials.

*Publication title: Real-time and label-free biosensing using moiré pattern generated by bioresponsive hydrogel (2022.11.29.)

Principal Researcher JaeJong Lee of the KIMM Department of Nano Manufacturing Technology, Yonsei University Professor Won-gun Koh, Severance Hospital Ophthalmology Professors Hyung Keun Lee and Professor Yong-woo Ji focused on the characteristics of the eye, which is directly connected to the brain, and detected various biomarkers* through trilateral cooperation among the KIMM, Yonsei University, and Severance Hospital. Through their research efforts, they developed an implantable biosensing system by mounting a bioresponsive hydrogel**-based sensing module capable of detecting various biomarkers* on an intraocular lens to express a signal in a moiré pattern***.

*Biomarker: An indicator that can detect changes in the body using proteins, DNA, etc.

**Hydrogel: A jelly-like substance that contains water as its main component.

***Moiré Patterns: A pattern characterized by regularly repeating shapes that are combined and recombined continuously, creating visual stripes according to differences in the overlapping shapes.

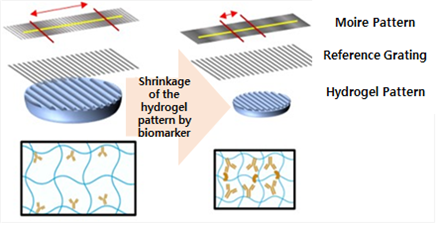

When the hydrogel pattern, to which the antibody is bound, reacts with the target biomarker, it contracts. The target biomarker is then detected using changes in the moiré signal, which are generated when the hydrogel pattern, which becomes narrower by the contraction response, overlaps with the designated reference grid. By using a moiré signal, detection is possible with much greater sensitivity than that of other methods that directly detect change in the hydrogel pattern.

Furthermore, unlike traditional biosensors, the moiré signal-based biomarker detection method can directly detect biomarkers without using electrochemical or fluorescent labels. Since this method does not require external power or a light source, one of its advantages is that it can be implanted within the body.

Principal Researchers JaeJong Lee and Geehong Kim of the KIMM Department of Nano Manufacturing Technology stated that the development of this technology is significant in that it can reduce social costs by diagnosing various neurological diseases, including dementia, which is one of the most common of such diseases that lead to social issues. They added that KIMM will continue to promote further research on this technology until it can be made available for commercial use.

This research study was carried out as part of the development of free-formed surface nano-manufacturing processes and systems and applications of non-blood disease monitoring devices under the Ministry of Science and ICT’s Nano Material Technology Development Project.

[Reference 1] Photos of research achievements

- Biomarker detection using reactive hydrogel patterns and moiré signals

- Lens used in the development of smart intraocular lenses

###

The Korea Institute of Machinery and Materials (KIMM) is a non-profit government-funded research institute under the Ministry of Science and ICT. Since its foundation in 1976, KIMM is contributing to economic growth of the nation by performing R&D on key technologies in machinery and materials, conducting reliability test evaluation, and commercializing the developed products and technologies.

These research efforts were carried out as part of the development of free-formed surface nano-manufacturing processes and systems and applications of non-blood disease monitoring devices under the Ministry of Science and ICT’s Nano Material Technology Development Project.

Credit : Korea Institute of Machinery and Materials (KIMM)

Usage Restrictions of Multimedia (Attachment File) : The sources of photos and research results from KIMM must be specified.