- Created2024.10.02

60% Lighter Automotive Air Duct Developed,

Set for Commercialization: Reduces Noise, Enhances Safety

KIMM develops a lightweight and airtight air duct using foam sheet material

with Eugene SMRC Automotive Techno Co., Ltd., and SH Korea Co.

□ A lightweight and airtight air duct, ready for immediate application in commercial vehicles, has been successfully developed. This domestically produced technology is expected to replace the current French-made air ducts, significantly contributing to enhancing the self-sufficiency of the domestic automotive industry.

□ The research team led by Senior Researcher Seunghoon Bae at the Busan Machinery Research Center of the Korea Institute of Machinery and Materials (President Seog-Hyeon Ryu, hereinafter KIMM), under the Ministry of Science and ICT, in collaboration with Yujin SMRC Automotive Tech Co., Ltd. (hereinafter Yujin SMRC A.T., represented by Heung-sik Kim) and SH Korea (represented by Sang-il Woo), has achieved a groundbreaking advancement in the manufacturing technology of air ducts for automotive cockpit modules. This technology has successfully met the specifications required for completed vehicles during performance evaluations and is now nearing commercialization.

* Cockpit Module: A central unit integrating key components of the driver's area, including the dashboard, air conditioning system, radio, clock, and storage compartments. It is designed for ease of use and information accessibility for drivers, making it a critical component in terms of design, convenience, and safety.

Senior Researcher Seunghoon Bae(right) of the Busan Machinery Research Center at the KIMM is examining the developed lightweight air duct.

□ Traditional air ducts, made from high-density polyethylene (HDPE), were heavy, had poor insulation, and resulted in significant heat loss. Additional issues included difficulty during assembly, noise generation, reduced fuel efficiency, and poor ride comfort for passengers. Moreover, in case of an accident, these ducts could break, posing a safety risk to drivers.

□ The newly developed air duct, created by a collaborative research team, features a weight reduction of approximately 60% compared to previous models by utilizing foam sheets. It also significantly improves airtightness, noise reduction, and safety.

□ The new air duct is manufactured through vacuum forming** and a hot knife process*** using foam sheet. This method drastically reduces the defect rate compared to traditional blow molding and allows for precise production of complex shapes, greatly enhancing manufacturing productivity. Additionally, by using polyethylene (PE) foam sheets, the thermal insulation has been improved, and noise reduction maximized, resulting in better fuel efficiency and a more comfortable driving experience.

**Vacuum Forming: A process where the foam sheet is preheated and placed into a mold, then formed into shape under vacuum pressure. This allows the foam sheet to fully adhere to the mold and take on the desired shape. The technology ensures the air duct is lighter than traditional blow-molded ducts while maintaining superior airtightness and precision in complex shapes.

***Hot Knife Process: A process in which the knife blade is preheated and used to cut the air duct according to its shape. The preheated blade ensures a clean cut and allows for precise trimming of the edges.

□ During the manufacturing process, the research team preheated the PE foam sheet and used suction molding to shape the material. The upper and lower foam sheets were bonded through compression, and the edges were precisely trimmed using a hot knife process for final finishing.

□ The research team also conducted rigorous performance evaluations to ensure the reliability of the developed air ducts, confirming that they meet the necessary specifications for automotive applications. During the testing process, the team also developed a technique to extract the dynamic properties of structures made of polymeric materials such as PE or polypropylene (PP).

□ Senior Researcher Seunghoon Bae of KIMM, who led this research, stated, "This product is expected to address the shortcomings of existing air ducts, and it will be applicable to various vehicle models in the future." Additionally, Sungbin Lim, Head of the Research Lab at Eugene SMRC A.T., commented, "This development has resulted in a component that excels in quality, cost efficiency, and weight reduction. We plan to enhance our competitiveness in both domestic and international markets through mass production."

□ This research was supported by the Ministry of Trade, Industry and Energy and the Korea Institute for Industrial Technology Evaluation and Planning, as part of the ‘Automotive Industry Technology Development (Green Car)’ project.

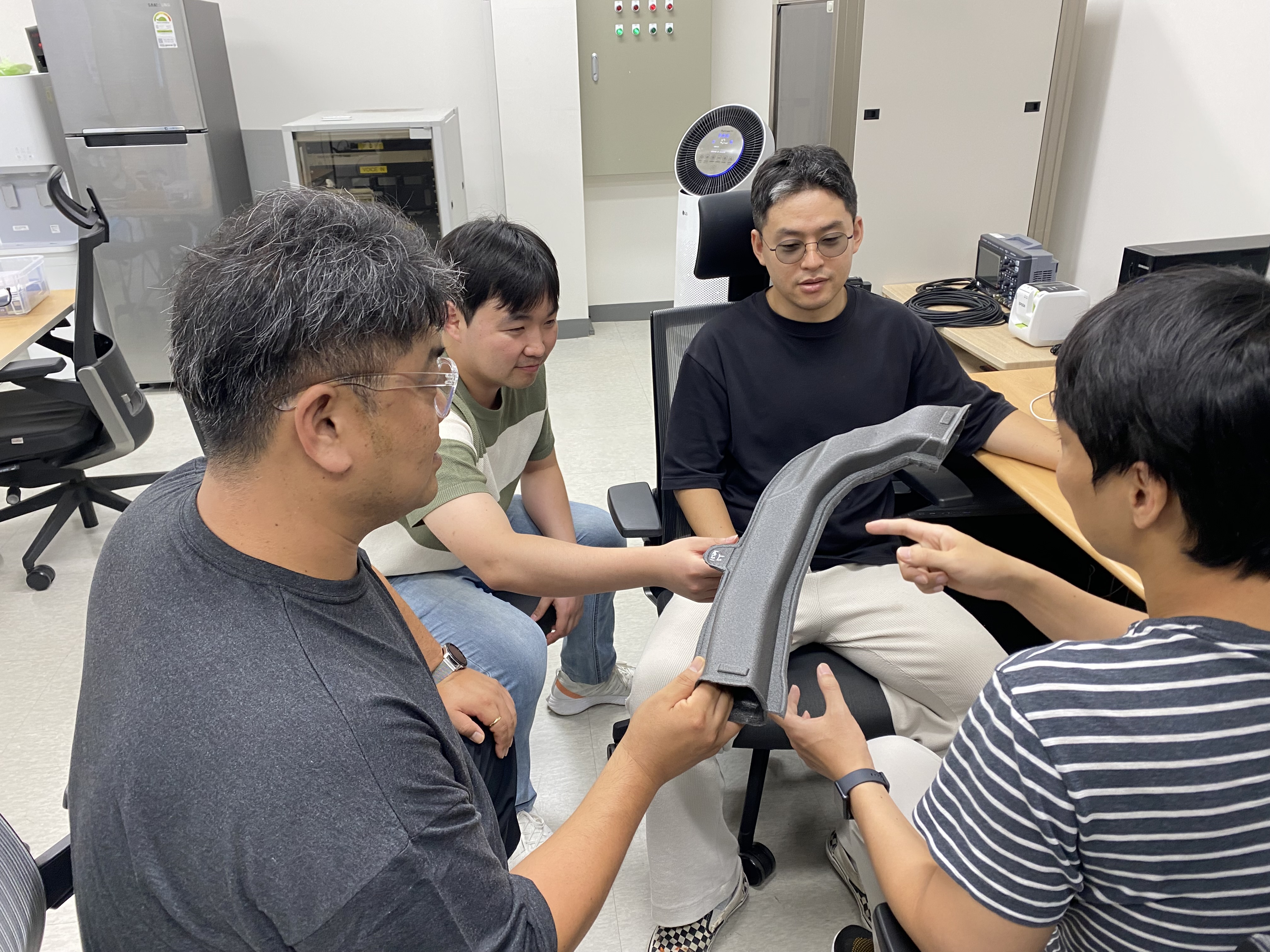

Seunghoon Bae, the senior researcher (second from the right) and his research team at the Busan Machinery Research Center of the KIMM are examining a prototype of the lightweight air duct.